ShaneAO Instrument Document¶

This document contains a description of the ShaneAO system goals, requirements, and design, and provides the observer’s and operator’s guides.

Version history

| Version | Description | Author | Date |

| 0.1 | Initial, according to Documentation Plan | Don Gavel | 7/16/2010 |

| 0.4 | Initial material in the Design Document section | Don Gavel | 3/8/2012 |

| 0.8 | Intermediate edits just before the design review, with pending items highlighted comments | Don Gavel | 4/16/2012 |

| 1.0 | Final edits for design review release | Don Gavel | 4/19/2012 |

| 1.4 | Fixes to cross-references | Don Gavel | 4/23/2012 |

| 1.5 | Converted to restructured text master version, Sphinx doc generators, and maintenance in a Git repository | Don Gavel | 9/13/2016 |

Introduction¶

The ShaneAO System is an adaptive optics imager and spectrograph designed for astronomical observations from 650 nm through 2.5 microns wavelength (part of R, and all of I, J, H, and K astronomical bands) using the Shane 3-meter telescope. The system uses adaptive optic technology for correction of atmospheric and telescope aberrations and a high-sensitivity infrared science detector. The imager is sampled at the diffraction-limit for wavelengths longer than 1.0 micron.

This document provides the top-level reference source for documentation of the system requirements and design, along with a guide to operation and maintenance.

The basic instrument capabilities and performance objectives are outlined in this chapter, which consists of material mostly taken from the original proposal to the National Science Foundation (*Gavel and Rockosi 2009*).

Background¶

The ShaneAO System, which is due to be commissioned in 2013, is an upgrade of the Lick 3-Meter Laser Guidestar AO system. The Lick AO system was installed as an experimental system in 1994 as one of the first astronomical AO systems to use a laser for a wavefront beacon. The AO system was upgraded and outfitted with a new infrared science camera, IRCAL, in 2000 (*Gavel, et. al., 2000*) and, after refurbishment and automation of the laser, was made available as a facility instrument in 2002. IRCAL used the then new PICNIC array detector, a derivative of the NICMOS effort for Hubble Space Telescope. IRCAL is Nyquist-sampled at K band given the AO corrected beam, is 256x256 pixels covering about 20 arcseconds of science field. Today, the Lick AO system typically delivers a Strehl of 0.3 in K band in laser guidestar observing.

The upgrade introduces a number of improvements that reflect the advances in technology made since 1994 and will provide considerable upgrade in performance as a result. First of all, the AO system will be improved to provide a typical Strehl of 0.3 in I band, opening up the I, J and H as well as K infrared bands to diffraction-limited imaging. Secondly, IRCAL will be retrofitted with a new Hawaii-2RG detector. The new detector has smaller pixels than the PICNIC so it is Nyquist-sampled at the diffraction-limit for λ>1.0 µm, and it has more pixels so that it more than adequately covers the original 20 arcsecond science field.

Example Science Uses¶

Lick Observatory is located at an elevation of 4200 feet atop Mt Hamilton east of San Jose. Time is assigned competitively with astronomers from all of the University of California (UC) 10 campuses and the associated labs (Lawrence Livermore National Lab, Lawrence Berkeley National Lab and the UC Berkeley Space Sciences Lab) eligible to apply. Through collaborations with other astronomers world-wide and including postdocs and graduate students in the UC system, Lick Observatory telescopes are available to a significant fraction of the US astronomical community. As we have completed the infrastructure to allow remote observations at Lick Observatory using stations at most of the UC campuses, the oversubscription rate on the 3-meter telescope is increasing. The site generally enjoys clear weather from May through November with good image quality. The location near to San Francisco Bay area communities has led to increasingly compromised sky brightness in the optical bandpasses, but for \(\lambda\)>800nm, the sky at Mt Hamilton is as dark as the best sites in the world.

The 3-meter telescope diffraction limit is \(\lambda(\mu m)\) x 0.07”. At \(\lambda =\) 1µ this is approximately an order of magnitude higher spatial resolution than delivered by the uncorrected atmosphere at the best ground-based sites. For point sources and background-limited observations (the norm at wavelengths longer than 1µ) the gains in sensitivity scale as the image size squared. There are a large number of science programs that have been built around imaging at this spatial resolution and obtaining spectra in the near-IR with very significantly reduced sky background based on the use of narrower slits in an AO-corrected focal plane. The 3-meter AO system is in regular use and has produced a number of interesting science results. In the Solar System, this resolution is sufficient to determine directly the shapes and rotation axes of asteroids and the incidence of binary asteroid systems (*Marchis et al. 2003*, *Drummond et al. 2008*) and to carry out spatially-resolved studies of the surfaces of planets and the larger moons (e.g. *Roe et al. 2001*). Other studies to date with the 3-meter AO system have been surveys for multiplicity among low-mass stars and stars known to harbor planets (*Patience et al. 2002*, *Marcy et al. 2001*, *Burgasser et al. 2005*), morphological studies of AGN and QSO host galaxies (Lacy et al. 2002, 2006), the environments of ULIRGs (*Laag et al. 2006*) and the centers of late-time galaxy collision remnants (*Bogdanovic et al. 2003*).

The current AO system at Lick Observatory was developed in the early 1990s and, although a pioneer system and state of the art for many years, there are limitations in delivered Strehl. The IR detector in IRCAL, the AO science camera, is several generations old. With the improved capabilities described in this program we believe the already high demand will go even higher and even anticipate some programs now carried out on the Keck system will be moved to the 3-meter.

The improved science reach for the new AO system comes from the increased throughput, higher Strehl and better camera focal plane sampling. All of the current programs will benefit greatly and new programs will now be possible. As discussed elsewhere, the astronomy community that has access to Lick Observatory is large and the science interests very broad. We discuss here a few example science programs, but this is by no means a complete list.

For point sources, the expected sensitivity gain will reduce the time to a reach a given S/N at fixed magnitude by factors of 18, 16 ,11.5 in J,H,K bands. Equivalently, the system brings within reach targets that have correspondingly smaller fluxes. For fixed luminosity limit, as for investigations of binarity fractions in nearby stars as a function of spectral type (e.g., *Goldman et al. 2008*), the increase in sensitivity corresponds to an increase in the available sample volume by a factor of 8 (H band). For proper motion studies, the sensitivity improvements increase the number of objects available in each field.

Studies of extended sources will also benefit from the upgrade. The improved Strehl will enable morphological classification to fainter magnitudes and of smaller galaxies, and detailed studies of debris disk and other extended features around stars. High Strehl also reduces the background in regions close to bright point sources. Two examples where this latter feature is powerful, discussed in more detail in the following paragraphs, are studies of QSO host galaxies and identification of line-of-sight absorbing systems.

That there is a tight connection between central black holes and the properties of their host galaxies is quantified by correlations like the M_BH-sigma relation (e.g., *Ferrarese & Merritt 2000*, *Gebhardt et al. 2000*). How the black hole controls the evolution of its host galaxy to establish this relation is one of the major open questions of galaxy formation. There are many pieces to understanding where quasars fit in the evolution of galaxies over cosmic time: how the quasar phase is triggered, how the lifetime of the quasar phase relates to the growth rate of the black hole, whether and how energy from BH accretion couples to the gas in the rest of the galaxy to drive the AGN feedback mechanisms invoked by galaxy evolution models, and what observational consequences AGN feedback has for the morphology and star formation rate of their host galaxies. The enormous database of known QSOs from surveys like the SDSS provides a great science opportunity using the improved sensitivity to undertake a systematic study of the properties of host galaxies of QSOs to address these questions.

A related observational problem is identification of the galaxies associated with QSO damped Lyman alpha absorption (DLA) systems. At low redshift (z<1) these systems have been shown (*Chen & Lanzetta 2003*), to be associated with star forming galaxies. The distribution of magnitude and surface brightnesses for the DLA galaxies is not well constrained by existing observations, and the low metalllicity values for low redshift DLAs (*Kulkarni 2004*) suggest that they might be low surface brightness or dwarf galaxies. DLAs are one of our only probes of the interstellar medium in high redshift galaxies, but in order to use that information we need low-redshift observations of the DLA galaxies to relate the gas-phase abundance measurements to luminosity, surface brightness, size and morphology.

Because a DLA line of sight intersects the absorbing galaxy where the baryons are in the disk and bulge, the starlight is likely to be concentrated at small projected distances from the QSO. Contamination from the QSO light raises the background and reduces the detection efficiency. As for the QSO host galaxies, the improvement in Strehl will lower the QSO contamination and enable detection of fainter DLA host galaxies. In a Gemini AO study of DLA systems at z<0.5, *Chun et al. (2006*) find likely candidates for the absorbing systems in all seven of their fields. The galaxies are faint, L < 0.1L*, and have scale lengths <~ 1 kpc. Despite their small sizes, these galaxies are resolved at z<0.5 in diffraction-limited imaging on the 3m, so the detection limits are a function of both surface brightness and total magnitude. We impose a reasonable surface brightness limit at one magnitude fainter in magnitudes arcsec2 than the surface brightness of the QSO host galaxy measured to 30% by *Lacy et al. (2002*) with the existing 3m AO system. This should be a worst-case estimate of the QSO contamination and does not account for the sensitivity gains from the new science detector. Using psf-convolved models of disk galaxies at z<0.5, we estimate a detection limit for these extended sources by scaling the point source sensitivity to account for the larger area, and therefore larger background uncertainty, in these resolved galaxies. We find that a search for DLA galaxies using the new 3m AO system should be able to detect and measure the structural properties of galaxies like those found by *Chun et al. (2006*) out to z=0.3.

Instrument Overview¶

Science Camera¶

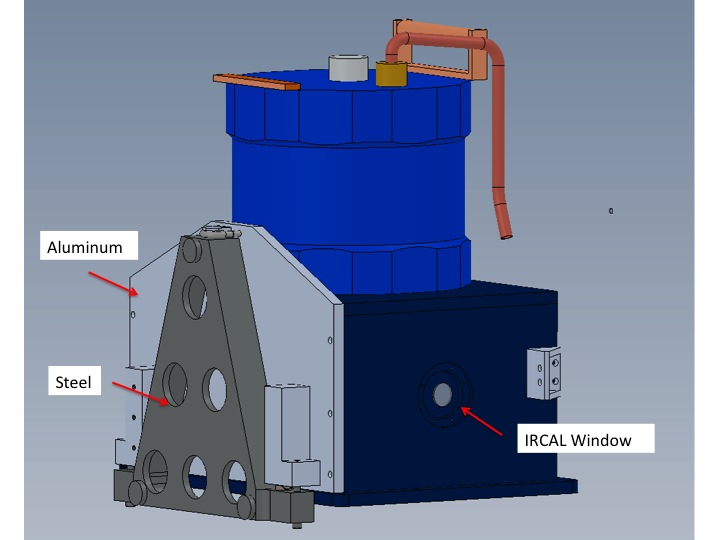

The infrared science camera, IRCAL, has imaging, spectroscopic, and polarimetric modes built around a Hawaii RG architecture detector. The detector is a Hawaii-2RG engineering grade device from Teledyne Labs with enough working area to capture the instrument’s field of view in both imaging and spectroscopy mode.

The optical design of IRCAL camera remains roughly the same as the original one that fed a PICNIC array. The dewar remains the same as the original, but the detector and optics are changed. The aperture wheel mechanism will be improved to allow better positioning control of the aperture.

IRCAL accepts a non-telecentric f/28.5 beam from the AO system. The camera relay optics consists of an off-axis parabola pair creating an intermediate collimated space that contains a pupil image plane. Two filter wheels are located in the collimated space and a fixed cold stop is located at the pupil plane. An aperture wheel is located at the input focal plane, ahead of the first off-axis parabola but still inside the dewar. The filter wheels in collimated space hold various spectral band and blocking filters, as well as a grism for spectroscopic mode and a Wollaston prism for polarimetric observations. The aperture wheel in the focal plane contains a choice of spectrograph slits for spectroscope mode, a cold finger for blocking a bright source in high contrast imaging, a 100 µm pinhole aperture, and an open position for regular imaging.

Adaptive Optics System¶

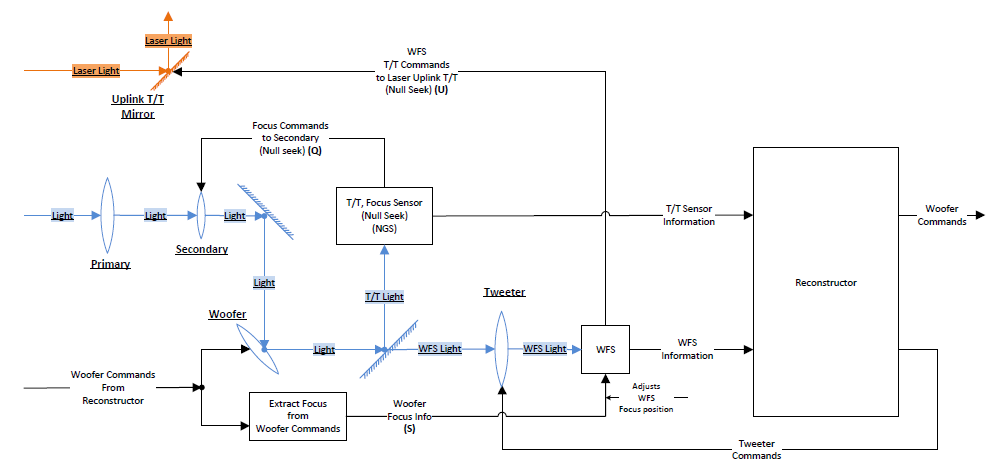

Adaptive optics correction is obtained with a pair of deformable mirrors. The first mirror, the “woofer,” provides tip-tilt and low-order (~40 Zernikes) correction at high stoke. The second mirror, the “tweeter,” provides the high-order (~700 degrees of freedom) correction but at low stoke. The cascade of stroke and order matches well with the dynamic range presented by the atmospheric turbulence.

Recent advances in silicon micromachining technology have led to the development of a microelectro-mechanical systems (MEMS) deformable mirror that enables high order wavefront correction at reasonable cost. Shane AO uses a 1024-actuator MEMS device (about 750 active actuators in the illuminated pupil) to correct the atmospheric phase aberrations ahead of the science imager. The large number of actuators, more than ten times that of the prior system, provides excellent wavefront correction and leads to very high Strehl across the near- infrared bands with some decent performance in the visible I-band as well.

The wavefront sensor is a Hartmann sensor built around a 160x160 pixel CCID66 high speed, low-noise CCD developed at Lincoln Laboratories. The Hartmann sensor can sample at either 8, 16 or 29 subapertures across the pupil diameter (43 cm, 20 cm and 10 cm subapertures mapped at the primary mirror, respectively). The selection allows for adjusting to laser guide star brightness (sodium density varies seasonally), or to the use of natural guide stars.

The AO system operates in closed loop mode. In closed loop, the wavefront sensor detects the guide star light after it has reflected off of both deformable mirrors. A dichroic splitter divides the light between the Hartmann wavefront sensor and the science camera, with longer wavelengths going to the science camera.

The AO system will be able to operate with both a laser guide star and natural guide star references. In laser guide star mode, a natural star in the surrounding 120 arcsecond diameter field is needed as an absolute tip/tilt reference since the laser beacon does not sense this mode. A beamsplitter in the wide-field relay transmits the natural star light to a separate high-speed tip/tilt sensor, while the 589 nm laser guidestar light goes to the Hartmann wavefront sensor whose pick-off is located in the narrow-field second relay.

Laser Guide Star¶

The laser provides a guidestar in science target fields where no suitably bright natural guidestar is available. The use of a laser guidestar greatly increases the fraction of the sky over which adaptive optics is useful, from less than 0.1% to over 30%. The dye laser for the Lick 3-meter AO system was the first to be used in astronomy for regular science observations (*Max et. al, Science, 1996*). The ShaneAO system uses a solid-state fiber laser, built by Lawrence Livermore National Laboratory. This laser is smaller, simpler to operate, and produces a brighter guide star than the earlier dye laser system.

The laser beam is launched from a refractive telescope mounted on the side of the Shane 3-meter telescope. It exits the telescope with a beam diameter of 20 cm and produces a guide star at the sodium mesosphere at 90 km altitude with a beam waist of approximately 3 m, or, resolved at the ground, about 1 arcsecond in extent. This is sufficiently “point-like” for the Hartmann sensor to operate as if the beacon were a point source.

The laser beam and resulting guide star are monochromatic at a narrow 589 nm line. Given the dichroic beam splitter arrangements, none of this light should appear on the science detector.

Observer’s Manual¶

This chapter describes how an observer uses the ShaneAO system to collect astronomical data. Observation generally consists of three steps: 1) observation planning, 2) data collection, and 3) data reduction and analysis. Each of these steps is explained below.

Observation Planning¶

The observer should carefully plan the observations for the night. Some advance planning and coordination with observatory enable a smooth and somewhat automatic observation sequence. Preparations include:

- Provide a science target list. Using the proper entry format will enable this list to be compatible for interface to the telescope control system, and, in LGS operational mode, for interface to Laser Clearing House for satellite avoidance.

- The observatory provides links to star charts and lists, ephemerides, twilight schedules, zenith and hour angles to help plan observation times.

- The observatory has links to databases to aid in choosing calibrators: e.g. photometric calibrators, astrometric calibrators.

- Sky or dome flats should be scheduled for the evenings/mornings surrounding observation and may include observation during certain allowed hours of twilight. The observatory staff or web site guides aid in planning the correct times and exposures for these.

- The observer will choose candidate tip/tilt stars for use in LGS mode. These will need to be within the tip/tilt radial field accepted by the tip/tilt sensor around the science target.

- A rough exposure time calculator, using the known throughput and emissivity characteristics of the instrument, will be available on-line.

Data Collection¶

This section will eventually discuss:

- Camera operation

- Means for quicklook of data during observation

- Temporary data location.

Data Reduction¶

The observatory maintains a long-life database of science data, which is accessible to the observers after observations were recorded. The data is stored in FITS format. Details of the FITS headers will be published as an appendix to this document. Fits header information includes position and status of the telescope, parameters of the science camera exposure, and condition and state of the adaptive optics system.

Archival data location and retrieval process…

The observatory will provide some recommended basic calibration reductions for the IRCAL camera and AO system. Observers are encouraged to contribute tools to the community of ShaneAO observers, which will be made available via web site.

Instrument Specifications¶

This chapter summarizes the operating modes, functional capabilities, and key parametric values of the ShaneAO instrument, giving the requirements for the design of the system.

Overall¶

- The system provides diffraction-limited imaging and spectroscopy in the near infrared wavelength range from 1.0 to 2.2 µm, corresponding to the astronomy science atmospheric transmission bands denoted as J, H, and K.

- The optical path input to the system accepts the f/17 cassegrain feed of the Shane telescope.

Science Camera¶

- The science camera optics provide diffraction-limited imaging and spectroscopy in the near infrared wavelength range from 1.0 to 2.2 µm, corresponding to the astronomy science atmospheric transmission bands denoted as J, H, and K, and the science detector provides Nyquist sampling of the diffraction limit in J-band.

- The science camera provides an unvignetted square field of view of 20” on a side (corresponding to a circular field of view of approximately 28”).

- The science camera will provide grism spectroscopy with a resolution of approximately R=500. Higher resolution is possible with an upgraded grism.

- The AO relay and dewar will have the capability of field rotation (by rotating the telescope tub) in order to orient science objects on the spectrograph slit.

- The science camera will provide the capability to do linear polarimetry with a waveplate external to the dewar and a Wollaston prism located within the dewar.

- The science camera and associated optics will fit in the existing IRCAL dewar.

AO System¶

Architecture¶

The Shane 3-m upgrade will adopt the “cascaded-relay” architecture. A wide-field, low-order and tip-tilt corrected relay will pass a 120” patrol-field to the tip/tilt and focus sensors. The central 20” of the field of view will pass through a second, narrow-field, high-order AO-corrected relay. The laser guide star wavefront sensor pick-off will be located in the second relay. IRCAL will be located at the focal plane of the second relay.

Optical¶

- The AO system accepts the f/17 beam from the Shane cassegrain feed and produces an f/28.5 beam as output to the science camera, allowing for the f/28.5 focus to be inside the IRCAL dewar at the aperture wheel.

- The AO system has a 1024 degree-of-freedom “tweeter” deformable mirror at a pupil conjugate and a low-order “woofer” deformable mirror mirror at a pupil conjugate (i.e. the AO optical relay has two pupil conjugate planes).

- The combination of woofer and tweeter deformable mirrors correct for tip/tilt; there is no separate tip/tilt mirror.

- The beam size at the pupil location of the deformable mirror is 31 deformable mirror actuator spacings. At 340 micron DM actuator pitch, this is 10.54 mm diameter.

- The dichroic split between science camera path and wavefront sensor path is after the deformable mirror.

- The “centerline” of the AO optical system is defined as that corresponding to the centerline of the Shane telescope cassegrain feed and is the same as the centerline of the IRCAL science camera.

- The tip/tilt sensor light path is split after the woofer deformable mirror.

- The tip/tilt sensor path is steerable for field selection of the tip/tilt star over a 60 arcsecond radius around the optical system centerline.

- The wavefront sensor light path is split after the tweeter deformable mirror.

- The wavefront sensor path is steerable for field selection of a guide star over a 14 arcsecond radius around the optical system centerline.

- Wavefront sensor field selection steering and tip/tilt sensor field selection steering are independent of each other.

Calibration¶

- When the system is dismounted from the telescope and in the laboratory, the system will have an atmosphere and telescope simulator that provides a beam identical to the Shane 3-meter telescope f/17 beam, simulated natural and laser guide stars, and moving atmospheric phase plates at ground and 5 km conjugates. This will be used during laboratory alignment of the system, not while on the telescope.

- The system will have the ability to move into place a calibration source at the telescope focus. The source will move completely out of the way to clear the entire AO system field of regard (60 arcseconds radius) during on-sky observation.

- The calibration sources are:

- laser (any line between 630-660)

- white light broadband covering 500 to 2200 nm.

Electronic¶

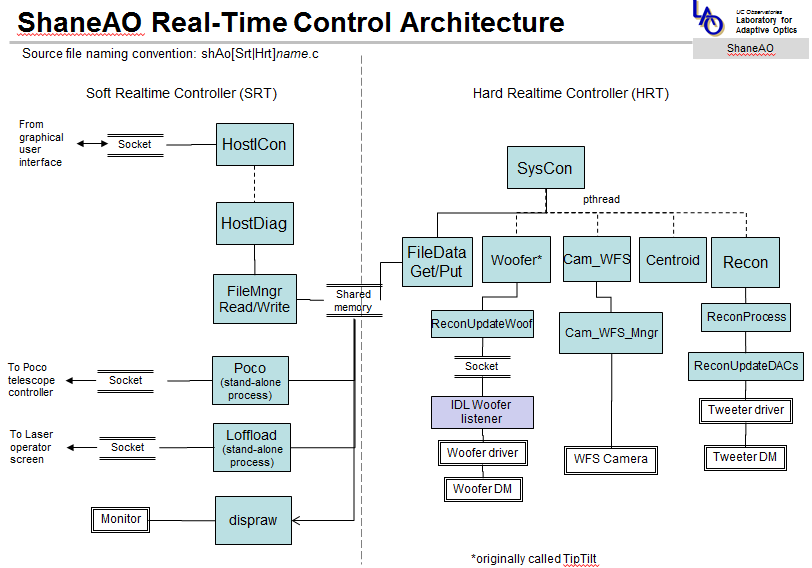

Wavefront Control System¶

- The AO reconstructor accepts input from the wavefront sensor camera and the tip/tilt sensor camera and produces outputs for both the woofer and tweeter deformable mirrors.

- The AO controller operates at up to 2kHz frame rate.

- The AO control loop has the following latencies: 500 microsecond camera exposure, 500 microsecond camera frame read, 500 microseconds compute latency and data transfer to DM driver.

- The AO control loop can operate at frame rates from a maximum of 2kHz to a minimum of 50 Hz.

- Details of the real-time control algorithm:

- Camera data processing: background subtraction and flat-fielding

- correction.

- Centroiding of Hartmann spots on a 4x4 pixel grid

- Slope-to-phase computation using an approach that allows for modal

- weighting, minimum variance estimation, and waffle-mode suppression.

- Wind prediction and forward wavefront control adjustment for the

- wind (See *Johnson, 2010*).

- Proportional-Integral feedback control, in the phase (actuator)

- space.

- Lead-lag compensation.

- Adjustable lead-lag weights.

- Plate-equation and non-linearity compensation for the MEMS

- deformable mirror.

- Separation of low order wavefront control from higher order

- wavefront control and transfer of these signals to the woofer and tweeter DM accordingly.

- In laser guide star mode the ability to sense tip/tilt using the

- natural guide star tip/tilt sensor.

- In laser guide star mode the ability to sense the tip/tilt portion

- of the LGS Hartmann sensor signal and use it to drive laser beam “uplink” tip/tilt.

Optical Bench Automation¶

The AO optical bench automation is as follows:

- Input beam steering from the telescope allows adjustment of the incoming beam for co-registration of telescope pupil to AO system pupil to an accuracy of 0.01 of a pupil diameter and a range of 1 pupil diameter. (Given that telescope pointing co-registers the focal center points.)

- Calibration insertion blocks the telescope beam and provides light from calibrator sources.

- The moving phase plates in the atmosphere and telescope simulator can run at a simulated 90 m/sec maximum speed down to 0 m/sec minimum speed with adjustment to a resolution of 1 m/sec.

- Field steering, pointing and centering, for the natural tip/tilt star. This is steerable to up to 60 arcseconds off-axis of centerline to an accuracy/resolution of 0.1 arcsecond in pointing and 0.01 aperture diameter in centering.

- Field steering, pointing and centering, for the wavefront sensor guide star. This is steerable up to 10 arcseconds off-axis of centerline to an accuracy/resolution of 0.1 arcsecond in pointing and 0.01 aperture diameter in centering.

- Science path pointing and centering. This is steerable up to 10 arcseconds off-axis of centerline to an accuracy/resolution of 0.1 arcsecond in pointing and 0.01 aperture diameter in centering.

- Science path focus is not adjustable but is aligned to a focus accuracy corresponding to less than 250 rms (1/4 wave at 1 micron wavelength) wavefront error. This is computed to be <250 microns in the f/28.5 beam.

- Hartmann sensor focus. Adjustable from 80 km focus to infinity focus with resolution of 1 km. This is continually on and adjusting during an exposure in laser guidestar mode.

- Polarimetry wave plate. Rotation stage adjustable over 360 degrees with an accuracy of 0.1 degree.

Deformable Mirrors¶

The cascaded relay design facilitates woofer/tweeter AO correction by providing two optical planes conjugate to the telescope pupil. Both pupil planes are located in collimated (with respect to the science light) spaces.

The woofer, an ALPAO Lo-speed DM 52, will have adequate stroke and bandwidth to provide both tip/tilt and low-order wavefront correction. The ALPAO Lo-speed DM52 has 52 actuators on a 2.5 mm pitch, for a maximum pupil diameter of 15 mm. It has 45 microns of surface tip/tilt peak-to-valley stroke at >200 Hz.

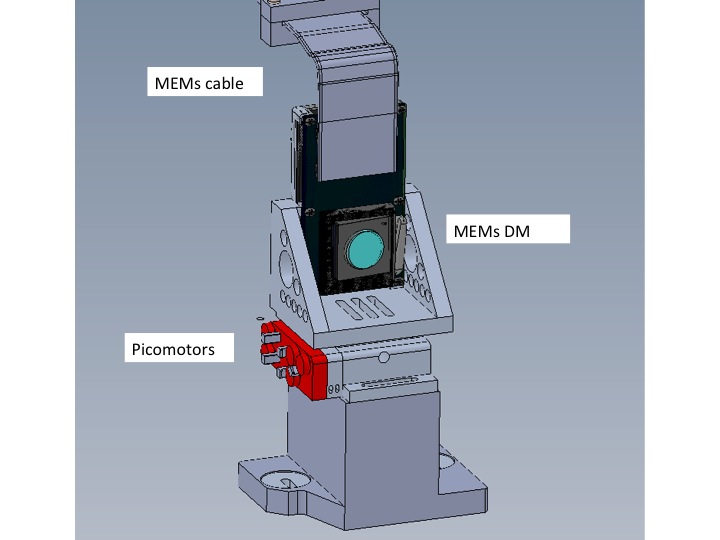

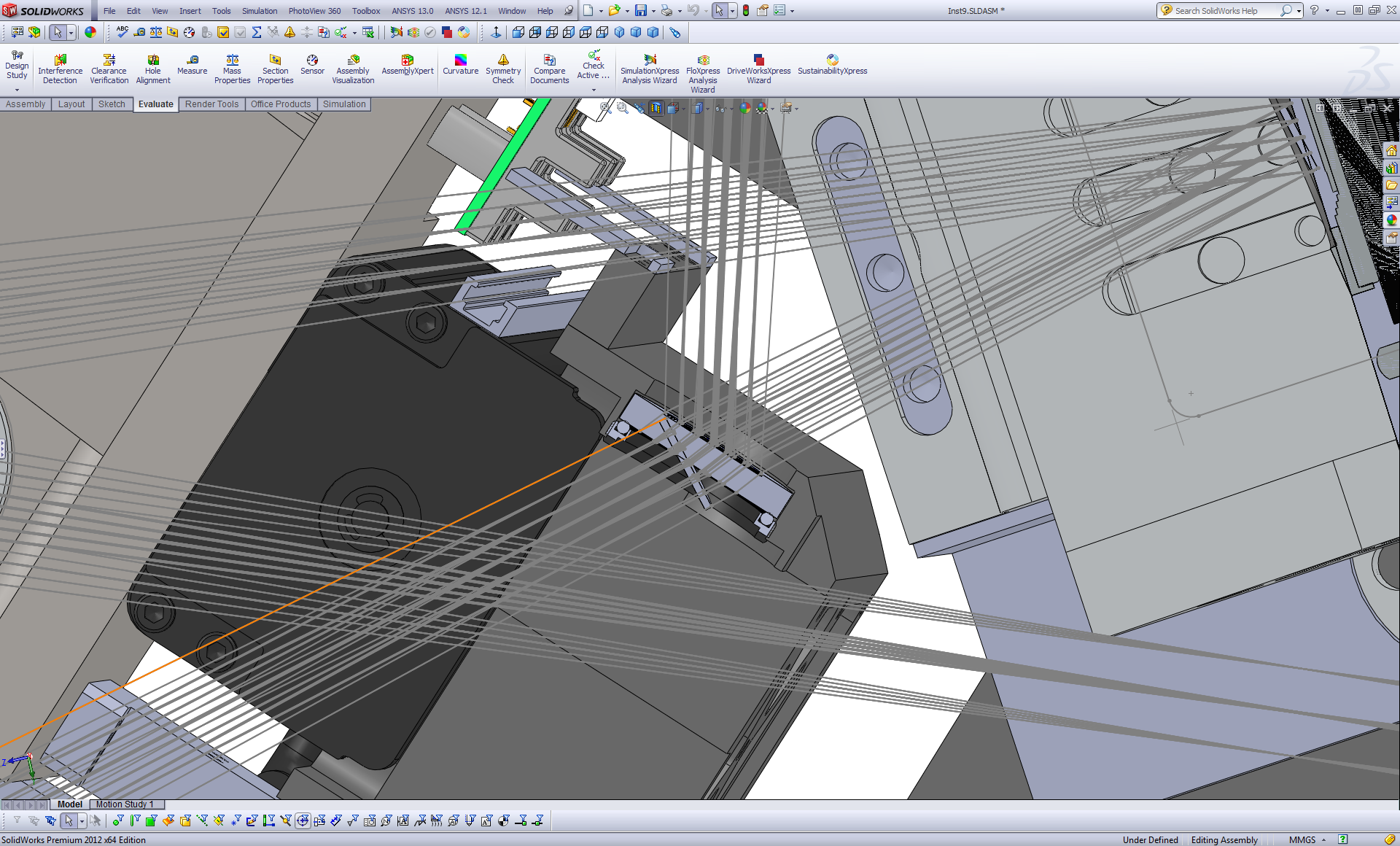

The tweeter DM, a Boston Mircromachines MEMs mirror, lies in the narrow-field second relay. It has 32x32 actuators on a 340 micron pitch, providing a 10.88 mm maximum pupil diameter. The MEMs device has 3 microns of mechanical multi-actuator stroke with bandwidths > 1 kHz.

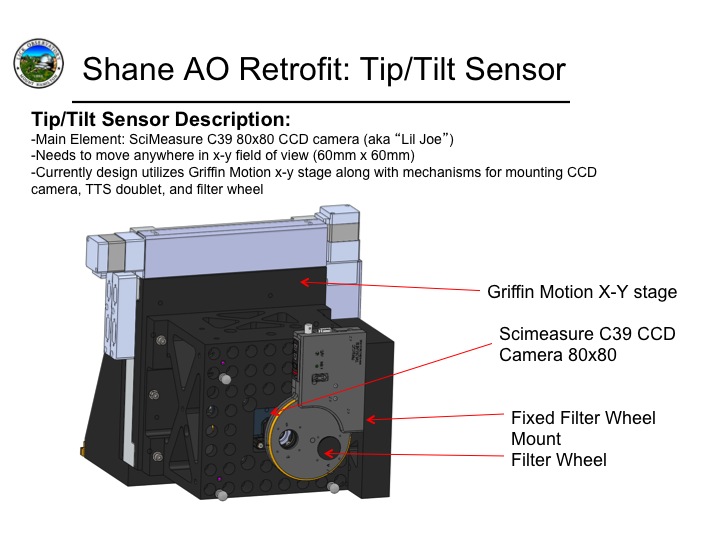

Tip/tilt Sensor¶

The pick-off for the tip/tilt/focus (TTFS) sensors will be located upstream of the focal plane of the 120” wide-field relay. The entire 120” diameter will be utilized as a patrol field for tip/tilt stars.

The tip-tilt pick-off will consist of a dichroic beamsplitter that reflects science and laser guide star light and transmits tip-tilt light to the tip-tilt sensor.

Beyond the pick-off, the TTFS relay will contain a reformatting lens to achieve the desired plate scale on the TTFS camera. This lens could be astigmatic if it is determined that focus sensing should be done by introducing astigmatism into the TT sensor beam. A small part of the light may also be picked here and directed to a separate truth wavefront sensor.

The detector of the TT sensor will remain the Scimeasure Little Joe that is currently part of the Lick 3-meter AO system. The current plate scale on the 80x80 detector of 0.33”/ pixel will also be adopted.

Laser/natural Guide Star Wavefront Sensor¶

After the collimating optic of the second relay and the tweeter deformable mirror, will be a selection of dichroics directing light to the laser/natural guide star wavefront sensor (WFS).

The WFS relay will contain a focusing lens to provide the WFS field stop with a focus. Between the focusing lens and the WFS field stop are a point-and-center pair of field steering mirrors. The WFS package must translate along the optical axis to accommodate focus shifts due to laser guide star zenith distance or operation in natural guide star mode.

The wavefront will be sampled at three scales depending on light levels of the reference source: 8x8, 15x15 and 29x29. The wavefront sensor camera will be a 160x160 pixel Scimeasure CCID66 with 21 µm pixels. Each subaperture will contain 4x4 pixels with a one pixel guard band.

Dichroic Selection for Science Operations¶

Dichroic passbands and specifications are officially stated in two spreadsheets “dichroics_worksheet.xls” (*KT* *link*) and “3mAO_dichroic_specs” (*KT* *link*). The first dichroic is used to select light for the tip/tilt sensor and the second shares the light between science detector and wavefront sensor.

The tip/tilt sensor is designed to use 600-900 nm wavelength light so the tip/tilt dichroic splitter is a 600-900 nm band pass in transmission. In NGS mode, a mirror is in place of this dichroic.

The wavefront sensor is designed to use 589 nm light in laser guidestar mode and 600-900 nm light in natural guidestar mode. The wavefront sensor dichroic is selected accordingly: a 589 narrow band reflection for LGS and 600-900 nm reflection for NGS.

The infrared science bands z, y, J, H, and K are served by the nominal dichroic selections in either LGS or NGS mode.

The astronomical I band goes down to 700 nm, so a different dichroic science/wfs dirchroic will need to be used for NGS observing. For cost and complexity reasons we are making provision for only two positions in the science/wfs dichroic selector, so for the special situation of I band science observations using a natural guide star, the existing NGS dichroic can be replaced manually.

LGS observing will be possible in I band if the TT dichroic is also replaced with a custom beamsplitter. However, this limits the tip/tilt sensitivity since I band light needs to be shared with the science arm. Purchase of the two additional dichroics needed for I band NGS and LGS science is a future upgrade option.

Table 1. Dichroic selection

| Observing Mode | Science | Dichroic 1 (T to t/t sensor) |

Dichroic 2 (R to WFS) |

| LGS | yzJHK | T 600-900 | R 589 |

| NGS | yzJHK | Mirror | R < 900 |

| LGS | I | T 600-700 | R 589 |

| NGS | I | Mirror | R < 700 |

Laser and Projection System¶

- Power: The laser output power is at least 9 watts at sodium D2

- Spectrum: consists of 9 narrow band CW lines separated by >200 MHz. “Narrow band” is less than 1 MHz. The line energies peak in the center and taper on a triangle shape on either size of center. Labeling the lines -4,-3,-2,-1,0,1,2,3,4, the lines have strength: 4, 8, 12, 16, 20, 16, 12, 8, 4 percent of the total laser power, respectively.

- Pulse formats: 1) pulsed at 2.7 kHz with a pulse width of 30 microseconds during which it is CW. 2) pulsed at 10 kHz with a pulse width of 3 microseconds during which it is CW. (Note: mode 2 is the present nominal design)

- Polarization: The laser output is linear polarization. Degree of linear polarization (Stokes Q2+U2I) > 99%. The laser projection system converts to circular; see below.

- The laser is remotely adjustable in wavelength for up to 5 GHz either side of the sodium D2 line with no reduction in output power.

- The laser has automatic wavelength control to keep centered at the sodium D2 line to an accuracy of 50 MHz.

- The sodium beacon generating laser is located on a stable platform off of the telescope.

- The high-power 589 nm laser light is fed from the output of the laser to the launch telescope via single mode polarization preserving optical fiber.

- The beam launch system enlarges the beam to 20 cm diameter for projection.

- The beam launch system has diagnostics for pointing and centering of the beam through the launch telescope with a range of 120 arcsec diameter for pointing, 1 beam diameter for centering, and an accuracy/resolution of 1 arcsec for pointing and 0.1 beam diameter for centering.

- The beam launch system has remotely operated beam pointing and centering mirrors. The mirrors are adjustable with a range of 120 arcsec diameter for pointing, 1 beam diameter for centering, and an accuracy/resolution of 1 arcsec for pointing and 0.1 beam diameter for centering.

- The beam launch system converts the output beam to circular polarization.

- For experimental purposes, the beam launch system has a mode that projects linear polarization. The switch from linear to circular polarization is remotely controlled.

Operator’s Manual¶

This section is to be completed prior to delivery of the instrument.

Instrument Mounting and Power Up¶

There are two types of power up: one when you mount AO system on telescope, the other on a nightly basis. We will utilize programmable power strips which are controlled remotely via the internet for all the below-mentioned devices.

Power up computers: All computers should be able to boot independently, so specific order does not matter. Start up all serving software, including motor control servers.

Power up motors, motor controllers, start up motor server (order depends on motor controllers selected).

Boot up the real-time computer (RTC).

Power up the cameras: wavefront sensor (WFS), tip/tilt/focus sensor (TTFS), and science camera (IRCAL). Note: need to check that the science detector and camera dewar is cold before turning on, so temperature sensor needs to be powered up before science camera.

Power up the deformable mirrors (DMs): woofer and tweeter.

Power up calibration sources.

LGS: Laser system has its own power-controls. The laser system uses an integrated Labview-based controller that does all status monitoring. A qualified laser technician must be present to supervise the laser startup. The Labview service software wrapper will broadcast its state using the Keyword system standard at the observatory. These broadcasts will be accessible by the AO system top-level controller so that laser status is coordinated with AO status, and with FITS header information.

There is an independent laser interlock safety system. Independent means, for safety, the system operates regardless of the state of any other computer or the network (although it does report status over the network, this status is not relied on for safety).

Software Startup Procedure

Science Camera

Setup user interface allows selection of IRCAL exposure time, filter wheel, aperture wheel, mosaicing or dithering pattern. During engineering, selection of region of interest and rapid readout modes are required. For science, slow readout with low noise is preferred.

Need to define combinations of dichroics/filters/states that conflict so software can alert user (for example, using same wavelength band for tip/tilt and science).

UI also allows co-adds of images, “snappy-diffs” (quick difference images with a micro-dither in between them for image location).

Quicklook on existing system allows check for overexposure, background. This could also indicated intensity at which detector becomes non-linear (less than saturation point). This is a cursor-based system presently. We may want to color-code saturated or non-linear pixels.

Logs – logging every exposure is a FITS file with a header. Need to determine header information, where data is stored, when data is stored, when header is written. A table with explanation of each header value is useful. Also should include observer’s autolog, single line for every exposure with your choice of information. Object name and comment field must be filled in by observer. Comments may not occur in FITS header, but should be in autolog.

Need to provide observers with location of data, location of autologs. Also may include environmental data not in FITS headers.

AO System

Servers, software and GUIs should start up automatically, even if on different computers. We should not have to start each program individually. Software includes RTC, GUIs, telemetry pipeline.

Check clocks to make sure all system clocks agree.

Calibrating the AO System

Make sure you have flat for WFS. If not, with calibration source not in path, record a background signal for the WFS.

Make sure you have current control matrix for WFS.

Turn on and move in calibration light source (CLS) at telescope focus.

Center CLS on IRCAL camera by moving CLS (need to make sure in software that IRCAL filters are out and exposure time is appropriate).

Adjust WFS pointing and centering until CLS well-aligned on WFS. WFS tip-tilt readings should be small. Subapertures should be evenly illuminated.

Close TT loop on WFS TT signal.

Take exposure on IRCAL science camera and measure position of CLS.

Adjust pointing and centering into WFS until CLS hits same spot on IRCAL as it did in step 6.

Put in white light source, and adjust position until tip is 0.

Optimize exposure time on WFS until desired intensity reached (existing system this was 1500 counts per subap).

Close TT and AO loops.

Perform image sharpening to Strehl > 0.9 on white light source.

Acquiring a Guide Star / Science Target

Guider is co-referenced to IRCAL science detector frame so it will reliably set science position.

After a long slew, pointing errors are possible. Use the following pointing correction:

- Slew to a V < 8 star near the science target (within 1 degree).

- Match telescope pointing location of the star with catalogued coordinates.

- Repoint the telescope to science target with newly calibrated pointing.

Find tip/tilt star in guide camera.

Move telescope to science field of view

Verify science target location with “snappy diff”.

Move field steering mirrors of TTF sensor, based on known position of science object with respect to tip/tilt star, to center TTS on tip/tilt sensor.

Adjust telescope focus to focus TT star on TT sensor.

If in NGS mode, move WFS field steering mirrors, based on known position of science object with respect to NGS, to center NGS on WFS field stop. In most cases in NGS mode, the science object will be the NGS.

Offset the telescope to blank sky to record a TT/WFS background signal.

Go back to telescope pointing which places science object at center of IRCAL.

Close the TT/woofer loop (woofer handles TT and low-order). If LGS, TT signal comes from TT sensor. If NGS, TT signal comes from NGS WFS.

Close the MEMs loop.

Projecting the Laser

Verify that conditions are acceptable for laser projection (radio communication with airplane safety spotters, lasing is good-to-go regarding satellite avoidance.)

Propagate laser.

Adjust focus stage of wavefront sensor (WFS) based on zenith distance of target.

Check laser guide star return signal levels on the wavefront sensor. If there is an error in relative positioning between the laser launch mechanisms and the wavefront sensor boresite, the signal may be low. If signal is low, repoint laser launch in a search pattern.

Tune off sodium line and acquire a background Rayleigh backscatter signal for the wavefront sensor.

Close the woofer control loop, tip/tilt mode, on the tip/tilt star (acquired in step 6).

Close higher order wavefront control loop (woofer and tweeter DMs).

Optimizing the Control Loops

- Optimize WFS frame rate, given signal level and seeing.

- Optimize loop gain (goal is to have this automated using real-time-controller’s (RTC) telemetry data analysis).

Laser Technical Manual¶

This section is to be written prior to delivery of the laser.

Operator’s Qualifications and Safety Considerations

System Startup

System Calibration

Pulse timing

Wavelength

Observing Operations

Tuning off and on sodium wavelength

Design Document¶

AO Optical¶

First Order Optical Layout¶

The adaptive optics system will be mounted at the Cassegrain focus of the Shane 120 inch telescope. Best-known parameters of the telescope Cassegrain focus are given in Table 2.

Table 2. Shane 120” telescope Cassegrain focus parameters.

| Mirrors | Primary, secondary |

| Coating: Aluminum | |

| Primary | Radius of curvature: 30.5 m |

| Diameter: 3.048 m | |

| Conic constant: -1 | |

| Secondary | Primary-secondary distance: 11.47 m |

| Final focal length: 53.410 m | |

| Radius of curvature: 10.58 | |

| Conic constant: -3.238 (estimated) | |

| Focal radius of curvature: 4.135 m | |

| Diameter: 0.9 m | |

| Output beam | Focal ratio: 17.52 |

| Exit pupil location:16.866 before focus | |

| Exit pupil size: 0.963 m | |

| Plate Scale | 0.259 mm/” |

| Focus Location | 1.778 m behind primary |

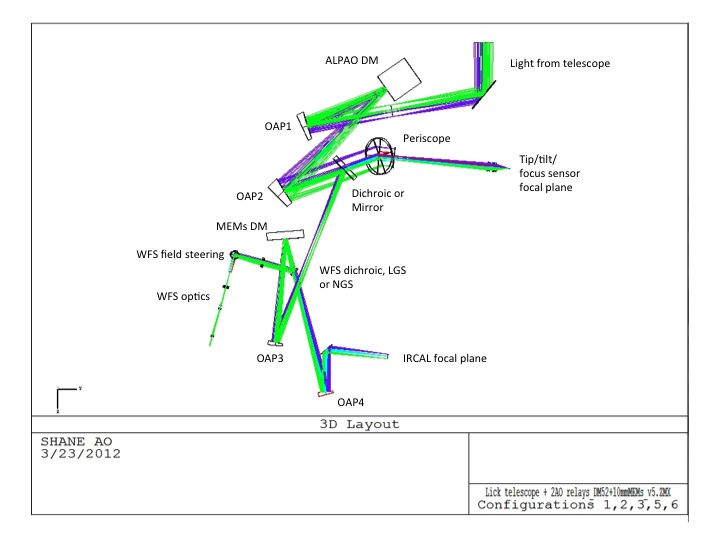

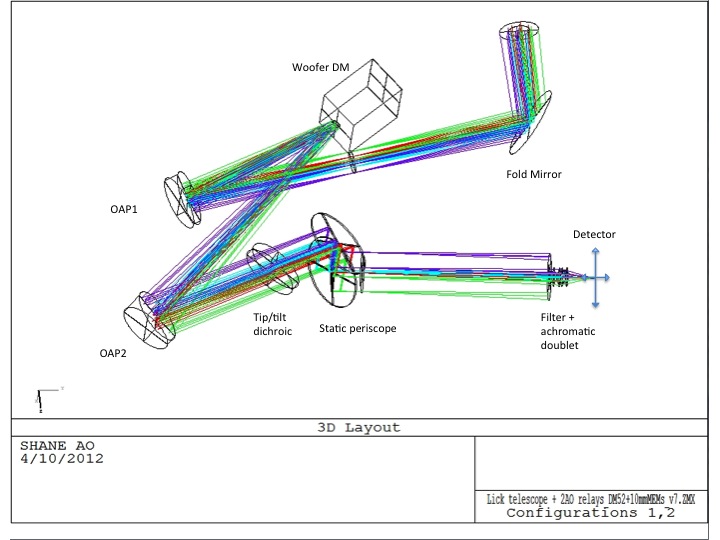

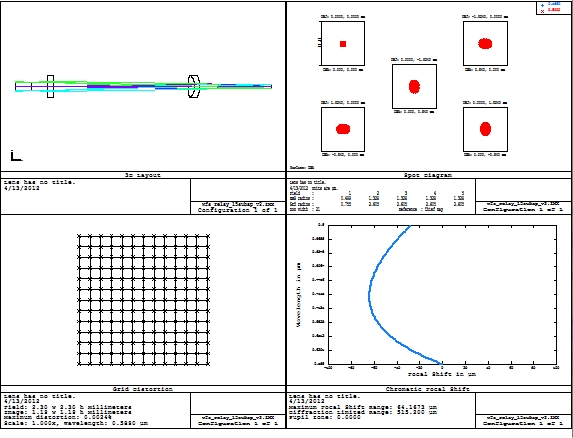

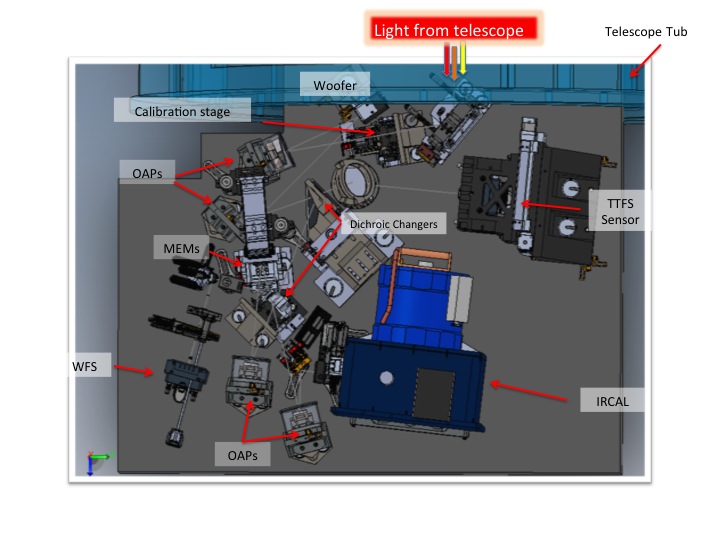

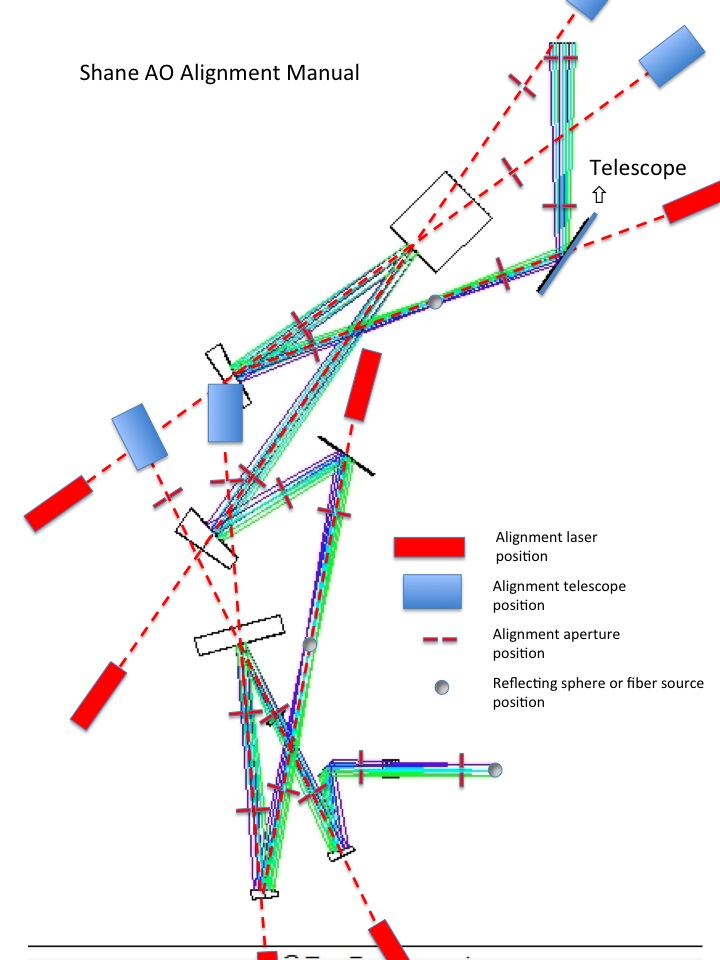

An annotated layout of the ShaneAO optical relay is shown in Figure 1. Each component of the optical system will be discussed in detail in the following sections.

Figure 1. Annotated optical layout of the AO relay.

Light from the telescope enters from the top of Figure 1 with a focal ratio of f/17-f/18, depending on secondary mirror position. The system has been designed for f/17.5, corresponding to the midpoint of the secondary travel.

The first, unmatched-OAP relay contains a 15 mm diameter low-order deformable mirror (DM) conjugate to the telescope primary and transmits a field-of-view (FOV) of 120” with an f/28.5 output.

A dichroic beamsplitter transmits light to the tip/tilt/focus sensor (TTFS), located after the focal plane of the first relay, providing a 120” patrol field for the tip/tilt reference star. The reflected light goes on to a second, matched-OAP relay containing a 32x32 actuator MEMs high-order DM, also conjugate to the telescope primary, and transmits an unvignetted 28” diameter FOV to the IRCAL science instrument A dichroic beamsplitter located in collimated space after the high-order DM directs non-science light to a wavefront sensor which can be used with both natural and laser guide stars.

First Relay¶

The first relay consists of two unmatched off-axis parabolas which, given an input beam of f/17.5, provide an output f/28.5 output focal ratio. The first parabola produces, in collimated space, a plane conjugate to the primary mirror at which the 15 mm low order DM is placed. The second OAP of the unmatched pair relays the Cassegrain focus to a second focal plane, with a focal ration of f/28.5. Near the focal plane of the OAP relay is a fixed 2-mirror periscope, directing the light to the tip/tilt/focus sensor. Preceding the periscope is a pick-off to send light to the second relay. The pick-off consists of a dichroic beamsplitter during laser operation, when the tip/tilt sensor is used, and a mirror during natural guide star observations.

For pupil alignment to the telescope, an additional fold mirror is located in the converging space before Cassegrain focus. During initial mounting to the telescope, the telescope pointing and this first fold mirror act as a pointing and centering pair.

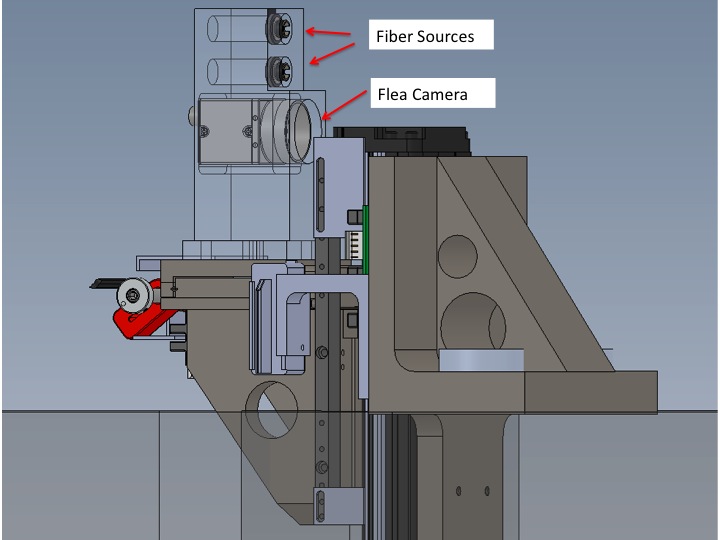

Calibration Source and Acquisition Camera¶

The first focus of the adaptive optics system will contain a selection of fiber sources to use during calibration and alignment of the system. These include a white light source and a red laser diode source. An acquisition camera is also located at the Cassegrain focus. This camera will be a Point Grey GigE Flea3 with a ½ inch sensor. At the 0.259 mm/” plate scale this camera will image a 49” field-of-view. It is intended for use during initial alignment to the telescope, and as a reference between the adaptive optics system and the 3-meter TUB guide camera.

Off-axis Parabolas¶

To first order, OAP1 has an apparent focal length that meets the requirement of a 15 mm pupil on the low order DM. The focal length can be found by the following relation,

where dDM is the low order DM pupil size of 15 mm, dPM is the primary mirror size of 3.048 m, and Ftel is the focal length of the telescope, 53.410 m. This gives a focal length for OAP1 of 262.8 mm.

The low-order DM follows OAP1 at a distance from OAP1 that will place it conjugate to the telescope primary, or

where t:sub:`pupil` is the distance to the telescope exit pupil from the telescope focus. Equation (2) gives a total OAP1 to low-order DM distance of 266.9 mm.

Finally, in order to match the current input f/# to IRCAL, we’ll need a slight magnification in the AO relay. It’s advantageous from a packaging standpoint to use OAP2 to achieve this magnification. To first order, the focal length of OAP2 will be given by

where f/#:sub:`out`=28.5 and f/#:sub:`in`=17.5, giving a focal length for OAP2 of 428 mm.

The numbers derived with Equations (1), (2), and (3) are first order approximations only. In fact, the pupil on the deformable mirror is undersized to account for many variables, including an uncertainty in the input f/# of the telescope, and also for elongation due to the DM’s tilt and pupil aberrations. Also, the focal lengths and distances derived above assume the parabola is used on-axis. The parent focal lengths (see Figure 2) of the off-axis parabolas were determined using Zemax. Table 3 gives actual specifications, determined in Zemax, for each of the optics in the AO relay.

Figure 2 Diagram of off-axis parabola (delineated by black cut-out) with respect to parent parabola.

Table 3. OAP specification for Shane AO

| Radius of Curvature (mm) | Diameter (mm) | Off-axis Distance (mm to center) |

|

| OAP1 | 456.0 | 75 | 60.0 |

| OAP2 | 742.0 | 75 | 167.3 |

| OAP3 | 549.6 | 40 | 77.2 |

| OAP4 | 549.6 | 40 | 77.2 |

Woofer Deformable Mirror¶

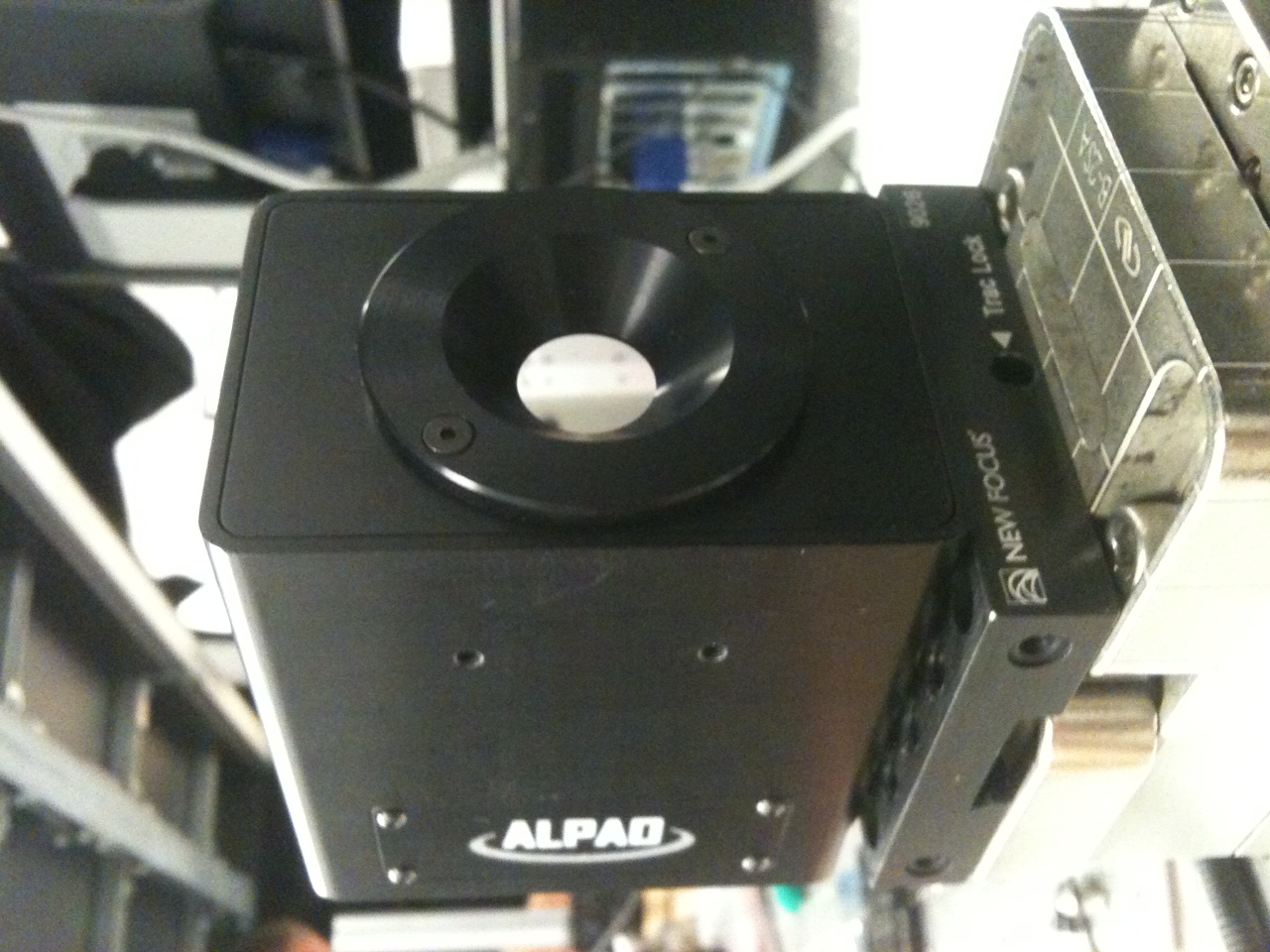

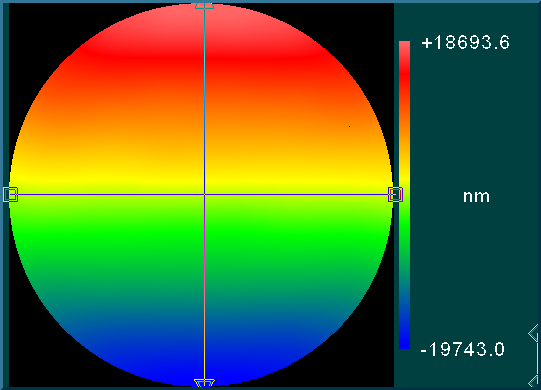

Low-order wavefront correction and tip/tilt are achieved with an ALPAO DM52-25-2.5 voice-coil actuated deformable mirror, shown in Figure 3. The mirror has 52 actuators on a 2.5mm pitch, and a useable pupil diameter of 15 mm. Its measured tip/tilt stroke is 40 μ P-V, surface, shown in Figure 4, and its inter-actuator stroke 8 μm P-V.

Figure 3. Woofer DM: ALPAO 52-actuator magnetically actuated membrane deformable mirror.

Figure 4. Measured tilt stroke, displayed as surface in nanometers.

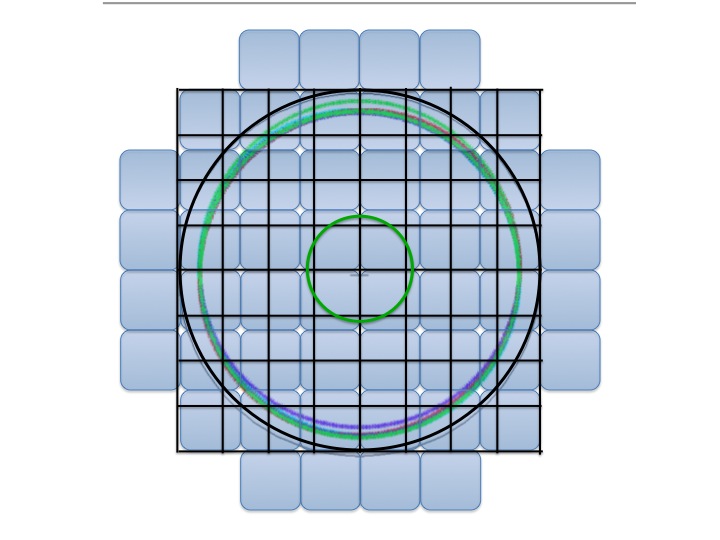

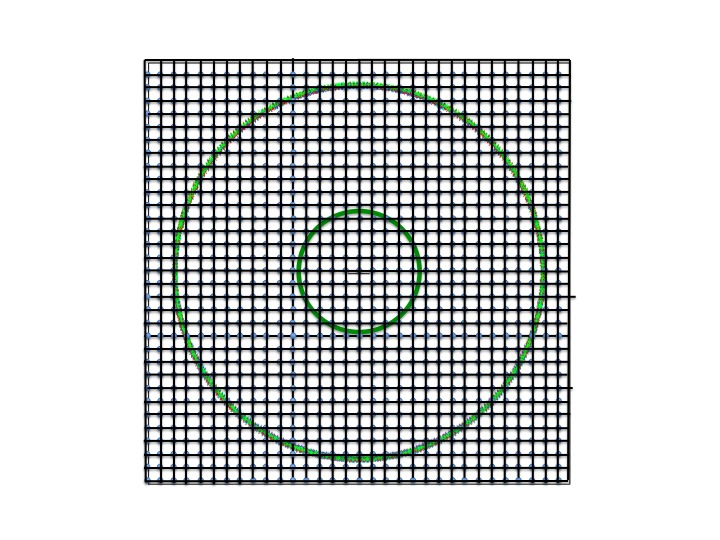

The mapping of the pupil on the mirror, and the mapping of the subapertures (in 8 x 8 sampling) is shown in Figure 5. Due to the 10° angle of incidence, the pupil is slightly (2.2%) elongated in the direction parallel to the optical table.

Figure 5. Mapping of the pupil (green/purple annulus) and subapertures (black grid) on the DM52. The actuators are shown as blue pads, with the 15 mm clear aperture of the membrane a black circle.

In Figure 5 the pink annulus represents the pupil imaged on the woofer. The black grid is the wavefront sensor subapertures, and the blue pads represent DM actuators. The ALPAO DM is coated with protected silver, having the reflectance characteristics show in Figure 6.

Figure 6. Measured reflectance of the protected silver coating on the ALPAO DM52-25.

Tip/tilt/focus Sensor (TTFS)¶

Laser guide stars do not provide an absolute reference object for tip, tilt and focus. During laser operation, a natural guide star is required to obtain the tip, tilt and focus information for correction of image motion and blurring.

Optical Feed¶

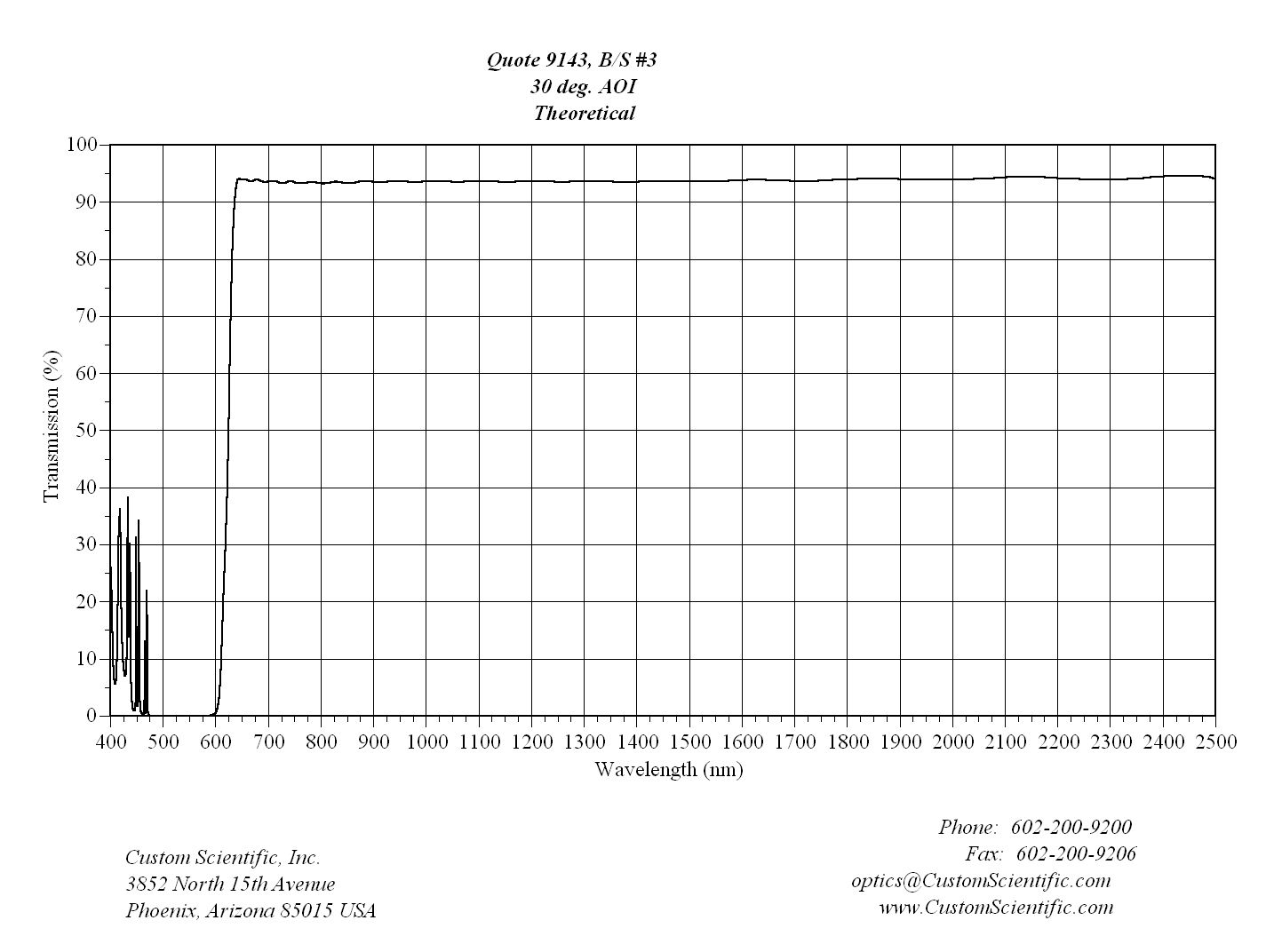

In the converging beam after OAP2 the science and laser guide star light is directed to a second OAP relay by a dichroic beamsplitter. During natural guide star adaptive optics operations, the dichroic beamsplitter is replaced by a mirror because a separate tip/tilt reference is not required. The dichroic beamsplitter allows transmission of visible wavelength light to the tip/tilt/focus sensor, while reflecting the J, H, and K bands to the science detector. The beamsplitter also reflects the laser guide star sodium wavelength (0.589 μm) to the second relay where the wavefront sensor is located.

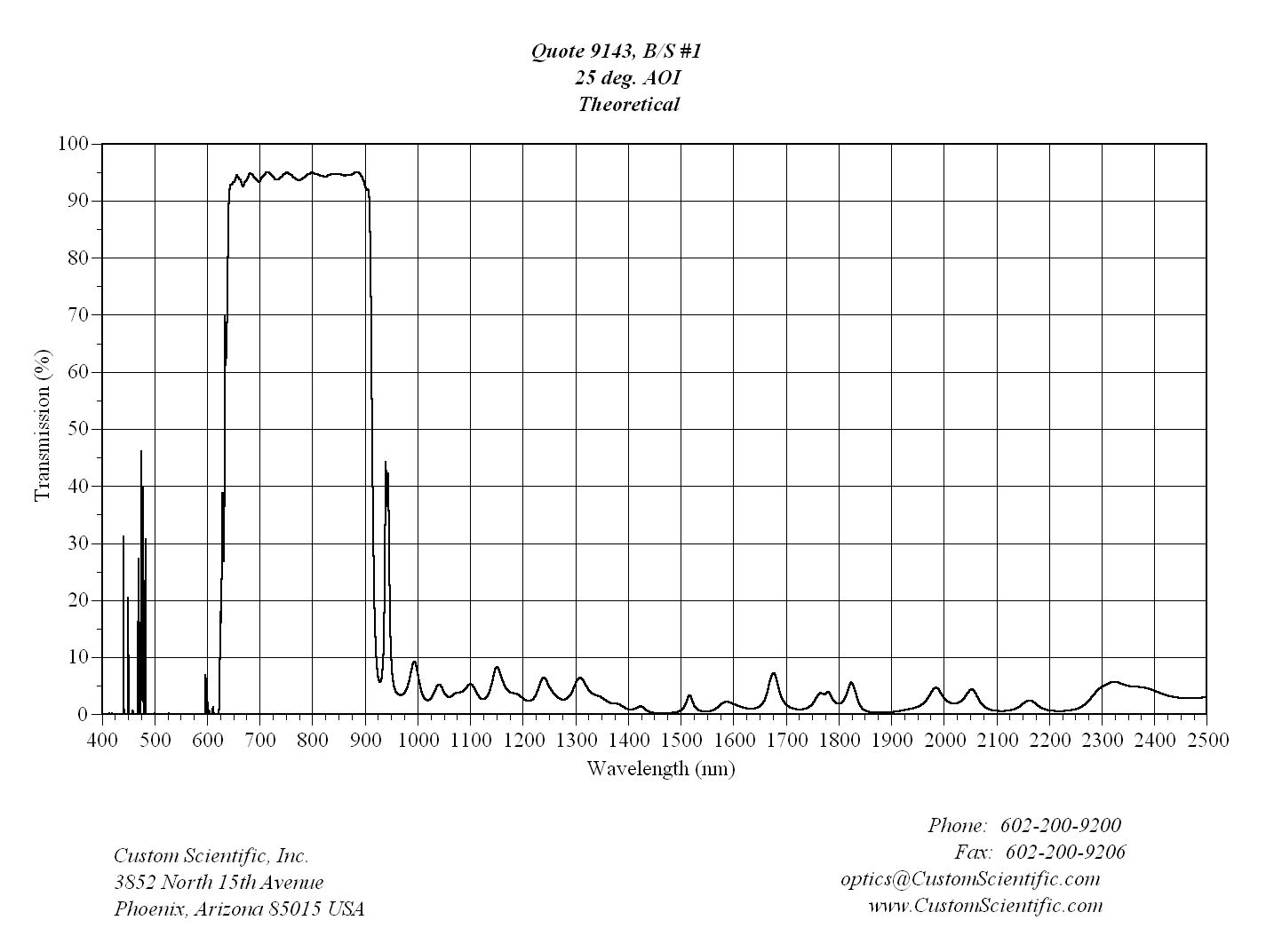

Figure 7 shows a design-theoretical curve provided by Custom Scientific for a TTFS dichroic beamsplitter with a guaranteed reflectance >99.5% at 589 nm. A dichroic beamsplitter that allows I-band science observations has also been specified for a future upgrade to visible light adaptive optics.

Figure 7. Theoretical transmission curve for the TTFS dichroic beamsplitter.

The converging beam from the first relay is steered by a fixed periscope to send the natural guide star light through to the tip/tilt sensor. The beam is reformatted by an achromatic doublet in order to achieve an acceptable plate scale on the tip/tilt sensor. Currently, and in the upgraded Shane AO system, the tip/tilt detector is the Scimeasure Little Joe, an 80x80 detector with 24 micron pixels. The pixels are binned 3x3, and have a plate scale of 1”/binned pixel, or 0.072 mm/arcsecond. To achieve the 0.072 mm/arcsecond on the tip/tilt detector will require a magnification of 5.84 for an effective f/# of 4.87 into the tip/tilt detector. Both the doublet and the Scimeasure detector are mounted on large-travel x-y stage that is able to patrol the entire field-of-regard.

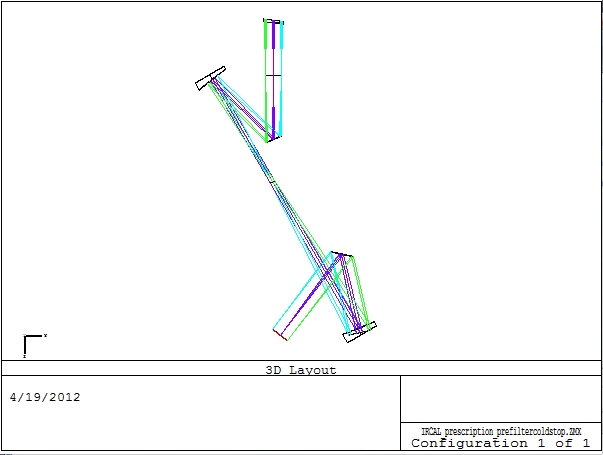

The Zemax drawing of the tip/tilt/focus sensor path is shown in Figure 8

Figure 8. Optical path to tip/tilt/focus sensor. Cassegrain input is at top of figure.

Slow-Focus Sensing Method¶

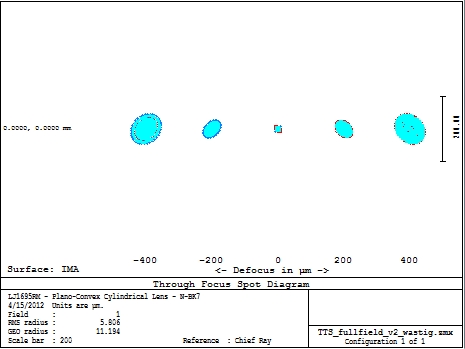

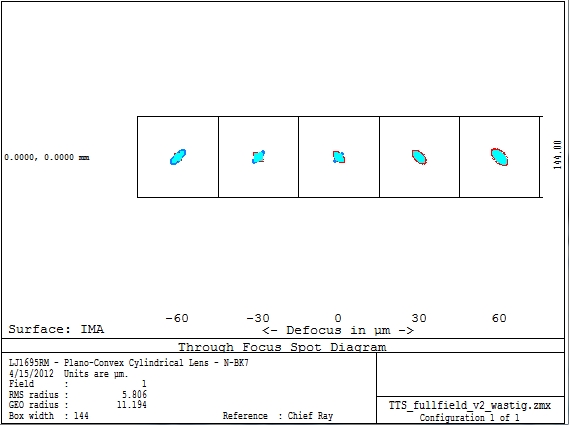

There is a requirement in the Shane AO system for slow focus sensing of a natural guide star. This can be accomplished by adding an astigmatic lens to the optical path of the tip/tilt sensor, at an orientation of 45° to the detector pixels. When the beam is in focus, the image on the detector will be exactly in between the saggital and transverse foci, with a diameter equal to the circle of least confusion. As the beam is defocused, the image will appear as an ellipse, then a line focus as it approaches either the saggital or transverse focus. The orientation of the line will be at ±45° to the detector pixels depending on the direction of defocus. The Zemax generated through-focus spot diagram in Figure 9 displays this effect.

Figure 9. Example of through-focus behavior of spots on tip/tilt/focus detector when a cylindrical lens is added to the optical path near the reimaging lens.

Second Relay¶

The purpose of the second relay is to relay a 28” diameter science field of view (inscribed square of 20” on a side) to the IRCAL focal plane, and relay an approximately 10 mm pupil image to the high order deformable mirror. The second relay consists of two matched off-axis parabolas which provide an f/28.5 output focal ratio into IRCAL. The first parabola produces, in collimated space, a plane conjugate to the primary mirror at which the 32x32 actuator, high-order DM is placed. A second OAP, matched to the first, produces a final focal plane located at the IRCAL aperture stop (within the IRCAL dewar). In the collimated space after the deformable mirror is a selectable dichroic beamsplitter, reflecting light to the laser/natural guide star wavefront sensor.

Off-axis Parabolas¶

To first order, OAP3 has an apparent focal length that meets the

requirement of an approximately 10 mm pupil on the low order DM. The

focal length of OAP3 can be found with , giving a focal length

of 285 mm for a pupil diameter of 10 mm on the MEMs. The beam entering

the second relay is telecentric, so the pupil image is located one focal

length away from OAP3.

The second relay maintains the f/# produced by the first relay as this is the legacy f/# going in to the IRCAL science instrument. OAP4 is therefore matched in focal length and off-axis angle to OAP3 (see Table 3).

Tweeter Deformable Mirror¶

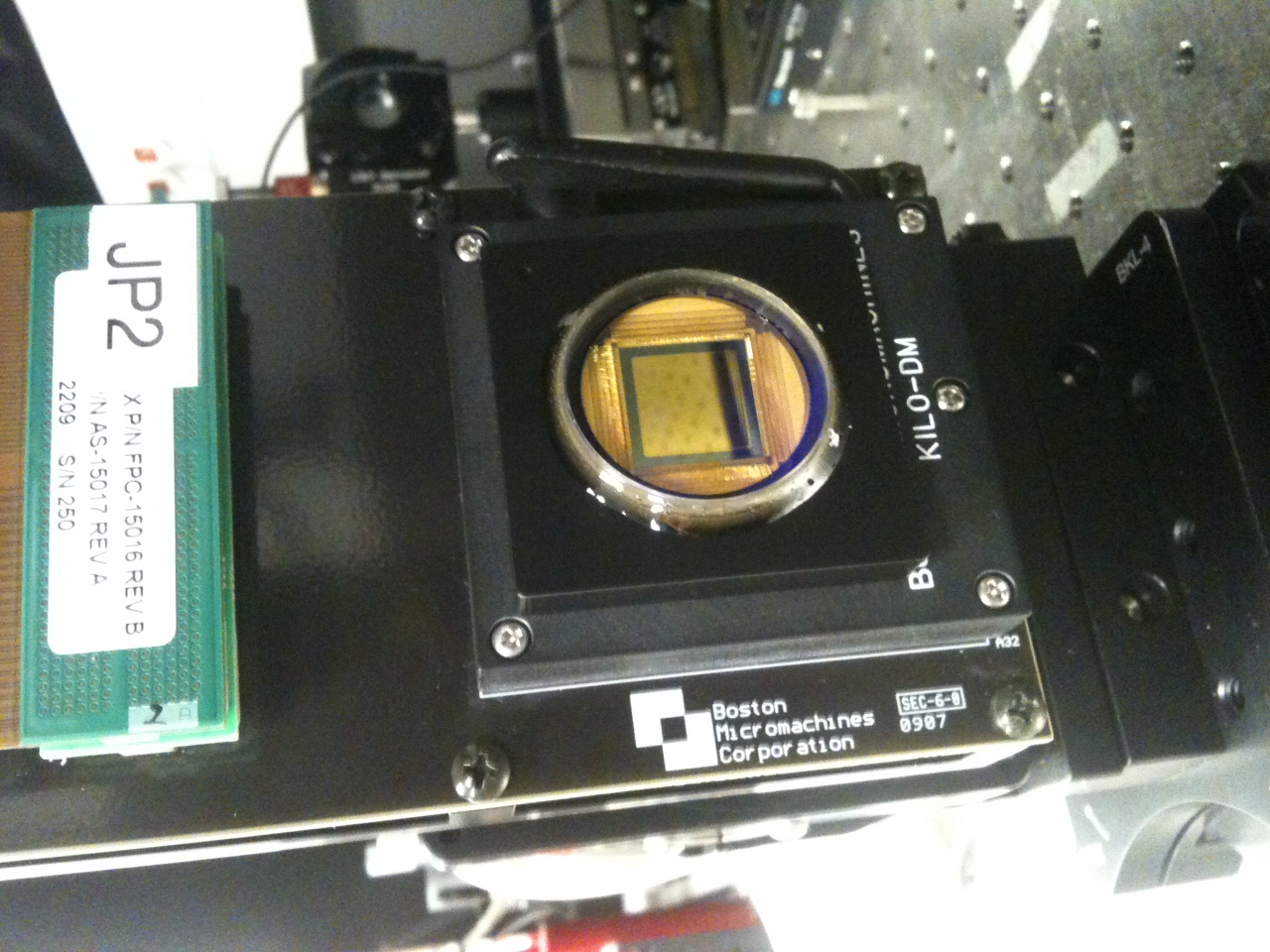

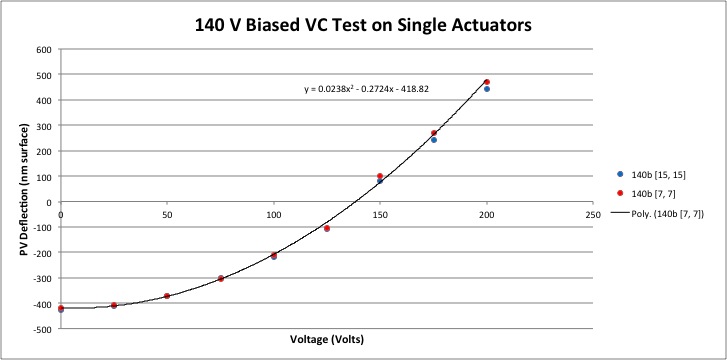

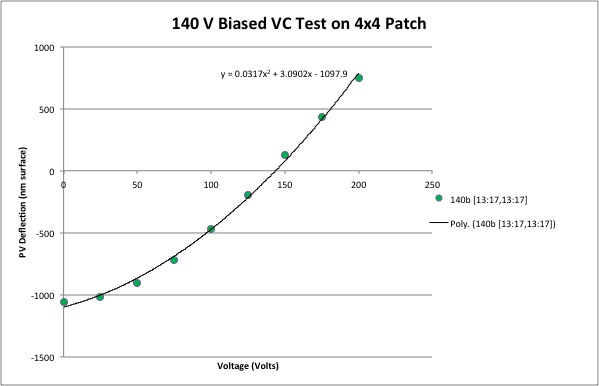

The high-order tweeter DM is a Boston Micromachines 32x32 actuator Kilo-DM. The actuators have a 0.340 mm pitch for a clear aperture of 10.88 mm. A photo of the Kilo-DM is shown in

. The bandwidth of the DM is several kilohertz, with a measured single-actuator stroke of 900 nm and a grouped actuator stroke of nearly 2 microns (Figure 11).

Figure 10. The Boston micromachines Kilo-DM under test at the Laboratory for Adaptive Optics.

Figure 11. Measured stroke of the Kilo-DM both for a single actuator (top) and a 4x4 group of actuators (bottom).

The continuous mirror facesheet is gold-coated, giving optimum reflectance for the near-infrared science light.. For environmental reasons (the MEMs DMs require low-humidity), a window is mounted to the front of the deformable mirror. The window is tilted 5° to divert ghost reflections to baffles, and AR coated to maximize transmission in both the IR and at 589 nm (since the wavefront sensor is located after the DM). The measured reflectance curve for the MEMs mirror is shown in Figure 12

Figure 12. Measured reflectance for the MEMs window anti-reflection coating. Y-axis is percent reflection, x in wavelength in nanometers. .

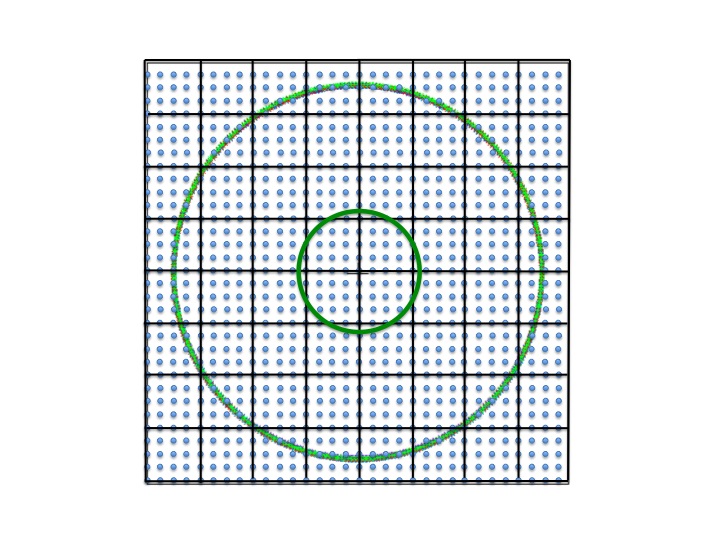

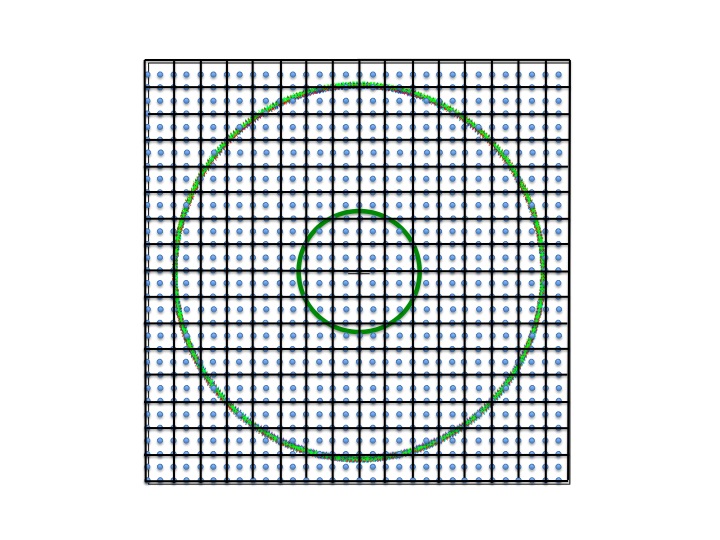

The mapping of the pupil on the MEMs device, and the wavefront sensor subapertures in 8x8, 16x16, and 32x32 subaperture mode are shown below in Figure 13, Figure 14, and Figure 15. Due to the 10° angle of incidence on the deformable mirror, the pupil will be elongated by approximately 2% in the direction parallel to the optical bench. This slight elongation is included in the figures.

Figure 13. Pupil mapping (green annulus) on the 32x32 MEMs device (actuators are blue dots) for the 8x8 subaperture case (black boxes are subapertures).

Figure 14. Pupil mapping (green annulus) on the 32x32 MEMs device (actuators are blue dots) for the 16x16 subaperture case (black boxes are subapertures).

Figure 15. Pupil mapping (green annulus) on the 32x32 MEMs device (actuators are blue dots, and are located at the corners of the subapertures) for the 32x32 subaperture case (black boxes).

Wavefront Sensor Pick-off¶

Following the MEMs deformable mirror is the pick-off to the laser/natural guide star wavefront sensor. With the wavefront sensor pick-off located after both deformable mirrors, the system will be able to operate in closed loop control.

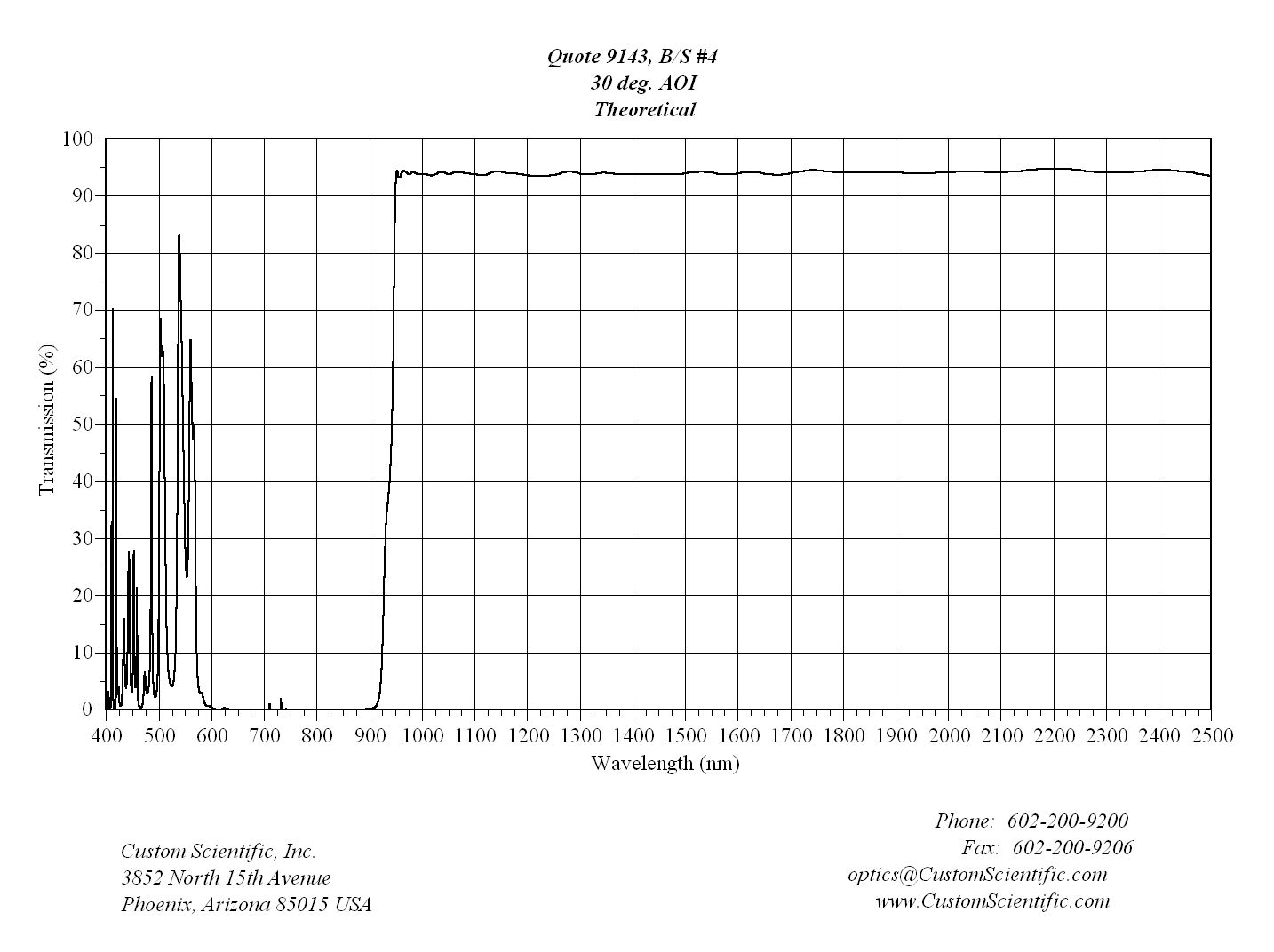

The pick-off will contain a choice of dichroic beamsplitters, depending on whether the observations use a natural or laser guide star, and the desired band for science observations. Theoretical transmission/reflectance curves for beamsplitters have been provided by Custom Scientific and are shown in Figure 16 and Figure 17.

Figure 16. Theoretical transmission/reflectance curve for the wavefront sensor dicbroic during laser guide star operations.

Figure 17. Theoretical transmission/reflectance curve for the wavefront sensor dichroic during natural guide star operations and IR science.

ADC¶

Although at this time there will not be support for visible light science with adaptive optics, it is believed that with a laser guide star upgrade, AO science in I-band will be achievable. An atmospheric dispersion compensator (ADC) will be required for observations in I-band. A preliminary design exists for an ADC on ShaneAO, but will not be implemented at this time.

Waveplate¶

For polarimetry the existing Lick 3m AO system employs a deployable half wave plate and Wollaston prism. The half wave plate is mounted within a rotation stage and sits outside (directly in front of) the IRCAL dewar. The Wollaston prism is contained in one of the filter wheels within IRCAL. The optics will remain in the upgraded ShaneAO system, although the cold stop will be moved upstream optically of the Wollaston in order to provide a consistent pupil for both polarizations. This will be accomplished by shifting the pupil image within IRCAL.

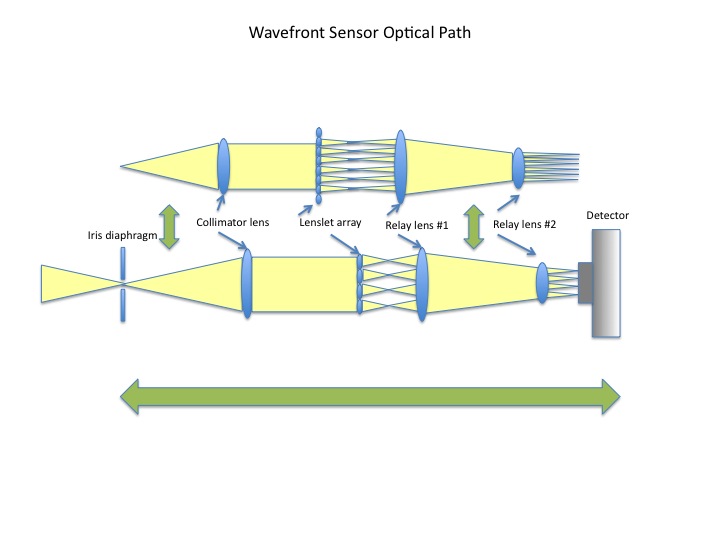

Wavefront Sensor¶

As indicated in section 7.1.4.3, the wavefront sensor pick-off is located optically downstream of both deformable mirrors. To maximize efficiency and performance at different guide star brightness levels and seeing conditions, a selection of two subaperture samplings is available, with the possibility of adding a third. The system provides the option of sampling 8x8 or 16x16 across the pupil (corresponding to 37.5 cm and 18.75 cm sampling on the primary mirror) with the ability to upgrade to a 30x30 sampling if a laser with sufficient return flux becomes available. During initial operation with the existing Lick laser, the wavefront sensor will be operating with 8x8 subaperture sampling.

Because the pick-off to the wavefront sensor is located in collimated space, a focusing achromatic lens provides an approximately f/17.5 input into the wavefront sensor optics. Field steering will be required, especially in natural guide star mode, when the guide star may be off-axis with respect to the science object. The patrol field for guide stars is the entire 28 arcsecond diameter of the science field.

Located at the focus of the existing wavefront sensor is an adjustable iris. Currently the iris is fully open during initial alignment, and is closed to the size of a subaperture during operation to block unwanted background light. It can also used to block one of a pair of binary stars.

The current system also contains a filter wheel in the wavefront sensor path, which provides a sodium transmission filter to block unwanted light from the wavefront sensor during guide star operation, and a selection of neutral density filters which are used primarily with the existing calibration source.

Because of the different sampling requirements, three separate optical designs were developed for the wavefront sensor. To facilitate switching between the configurations, an operation that may occur several times during the night (as, for example, the observer changes from natural guide star to laser guide star observations), all three optical designs have the same length between iris and detector as depicted in Figure 18. Each of the configurations have diiferent collimating lenses, lenslet arrays, and spot relay lenses. All three relays were designed to be achromatic between 0.6 and 0.9 microns, the wavelength range over which natural guide stars are measured. The lenses will be AR coated to maximize throughput at 0.589 nm. The parameters for the three configurations are outlined in Table 4.

Table 4. Parameters of three configurations of wavefront sensor

| # subapertures | Pixels/subaperture | Lenslet pitch (mm) | Relay magnification | Pixel scale (“/pixel) |

| 8 | 5 | 0.300 | 0.7 | 2.06 |

| 16 | 5 | 0.203 | 0.517 | 1.56 |

| 30 | 5 | 0.150 | 0.350 | 1.30 |

Figure 18. Cartoon representation of two wavefront sensor optical layouts. The two configurations are the same length between field stop and detector to simplify switching. Each of the configurations has a different collimating lens, lenslet array, and spot relay optics.

Science Camera Optical¶

Optical Design¶

The heart of the upgrade to the science camera will be the exchange of the 256x256 PICNIC array for a Teledyne H2RG engineering grade, with guaranteed 1k x 1k useable pixels infrared detector. The detector has 14.6 e- single CDS read (10.6 seconds), 5.25 e- Fowler-32 (340 seconds) readout. It has a quantum efficiency for wavelengths of 0.6-1.0 μm of 82%m, and a quantum efficiency for wavelengths >1.0 μm of 85%. The detector comes with a cryo-ASIC which will be incorporated into the dewar.

It was our intent to reuse as much of the existing hardware in the IRCAL dewar as possible. The optical design inside the dewar consists of an unmatched pair of off-axis aspheres with two fold mirrors for packaging. The dewar also contains an aperture wheel with a selection of slits, pinholes, an occulting finger and an open position, and two filter wheels containing a variety of bandpass filters for use in the near infrared. The filter wheels also contain two grisms – one standard grism with a resolution of about 500, and an experimental silicon grism with a resolution near 10,000. As mentioned in section 7.1.4.5 the filter wheel contains a Wollaston prism for polarimetry studies.

IRCAL was designed to be diffraction limited and sampled at K-band. Shane AO will provide diffraction-limited imaging and sampling also in J and H bands. The H2RG detector’s pixels are 18 pixels, and to cover the same field of view as the current PICNIC array’s 256x256 pixels requires approximately 600x600 pixels.

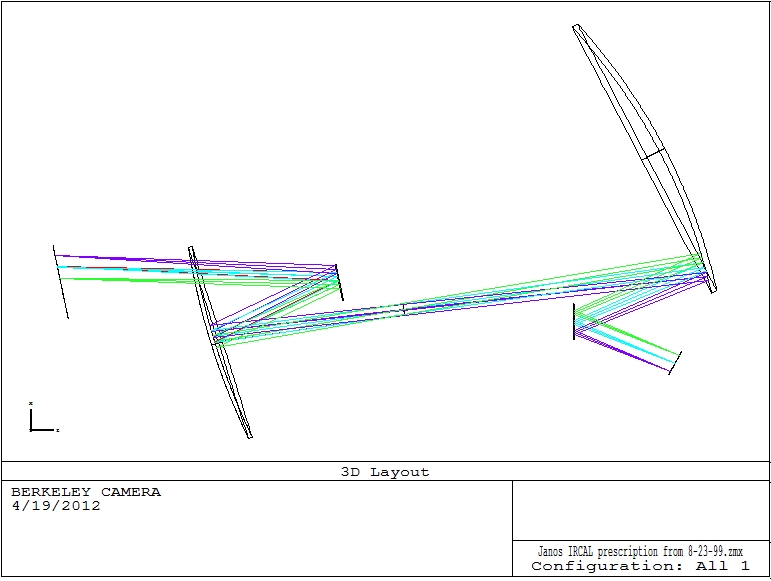

Figure 19. The IRCAL optical layout based on the Zemax file provided by IR Labs. Light enters from the AO relay to the left. The cold stop lies in the collimated space between the aspheres.

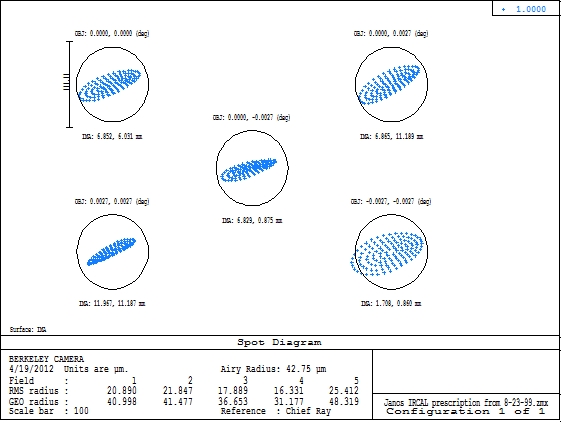

Figure 20. The Zemax report to the left shows the geometric spot analysis for the optical layout given in Figure 19. The circles represent the diffraction limit at 1 μm. The figure on the right is the footprint diagram at the cold stop. Each colored circle represents the pupil image produced by different field points.

Figure 19 shows the existing optical design based on a Zemax file provided by IR Labs. The off-axis aspheres are not configured in their optimum orientation for good imaging in the existing system, as can be seen by the spot diagram in Figure 20. Figure 20 also indicates that the pupil is either highly aberrated or tilted at the cold stop. Based on this analysis, the pupil image does not completely fill the 5 mm cold stop, so it is very possible that stray thermal emission is getting past the cold stop. It was suggested by IRCAL’s designers that an upgraded optical design would ensure diffraction-limited performance at the shorter wavelengths, and we believe the high background presently seen on IRCAL could be remedied by a better analysis of the pupil image. The upgraded design has the following goals:

- Diffraction-limited in J, H, and K.

- Packaging that would allow the optics and new H2RG detector to fit in the existing dewar.

- Movement of the cold stop to a position upstream of the filter wheels. This ensures a constant point spread function for both beams of the Wollaston and the entire spectrum diffracted by the grism.

The new optical design is shown in Figure 21. The pupil within IRCAL has been shifted by moving OAP4 in the 2nd relay. The OAPs are being used in their best possible configuration for imaging. The location of the focal plane allows sufficient space for the H2RG detector and ASIC.

Figure 21. The new optical design for IRCAL. Light is entering from the AO relay at the top of the figure. IRCAL’s tilted window can be seen as the first surface. The cold stop lies at the plane drawn in the collimated space between the two OAPs. The new fold arrangement of OAP2 and the second fold mirror allows plenty of space for the new infrared detector package.

The new AO system will allow telescope tub rotation, enabling orientation of the science object on the slit or occulting finger. As the tub rotates, the secondary support spiders will also appear to rotate as seen at the pupil image at the science camera’s cold stop. In the existing system the cold stop has occluding spiders to block the secondary emission. In the upgraded system will not have these spiders since it is impractical to co-rotate the mask inside the dewar. The cold stop will still have a secondary obscuration, implemented by photo lithography on glass substrate. This of course adds two additional cold surfaces in the science path.

Optical System Performance¶

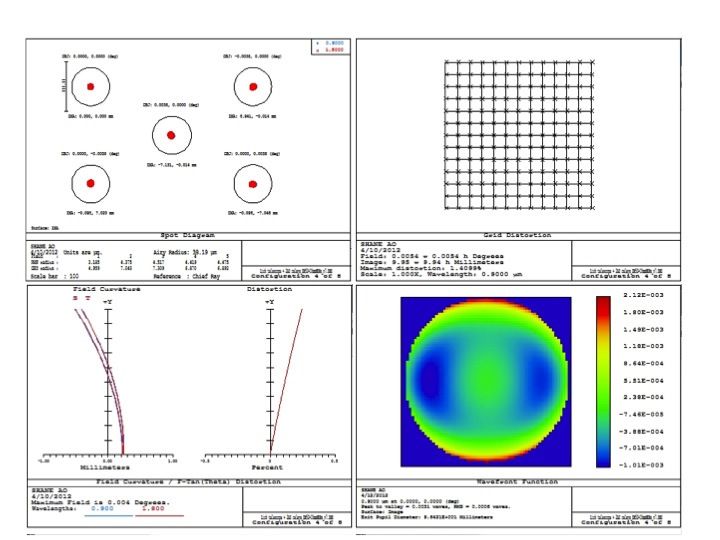

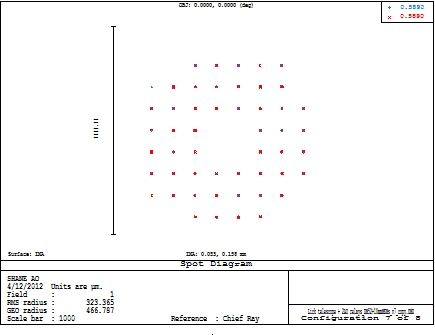

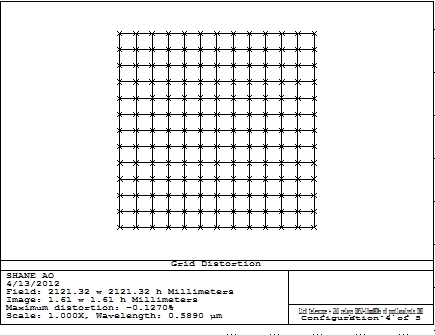

The science path includes the entirety of the OAP relay and the optics within the IRCAL dewar. Results of the image analysis are shown in Figure 22. The image is diffraction-limited in J-band at all points in the field-of-view. The image distortion is 1.4% over the field of view. It should be noted that the image plane at the focus of the adaptive optics relay (at the aperture stop of IRCAL) has less than a percent of distortion – the IRCAL optics are causing the majority of the image distortion. The field curvature is significant at the IRCAL focal plane, almost 0.7 mm sag, but does not cause the images at the extreme field points to become blurred beyond the diffraction limit. The wavefront error map shown in Figure 22 represents the output of the AO system, giving an on-axis wavefront error of only 3 nm peak-to-valley as designed.

Figure 22 System performance at IRCAL detector focal plane. *Top left* shows the geometric spot diagrams for on-axis and four extreme field positions at J and K bands, well within the diffraction spot size at J-band indicated by the black circles. *Top right* displays the grid distortion map for the full 20 arcsecond field. Maximum grid distortion is 1.4%. *Bottom left* displays the field curvature and distortion. Though field curvature is present, it does not contribute significantly to degradation of the image (as seen in the spot diagram). Finally, *bottom right* shows a map of the aberrated wavefront at the focal plane, with a magnitude of approximately 5 nm peak-to-valley.

Tip/tilt/focus Sensor¶

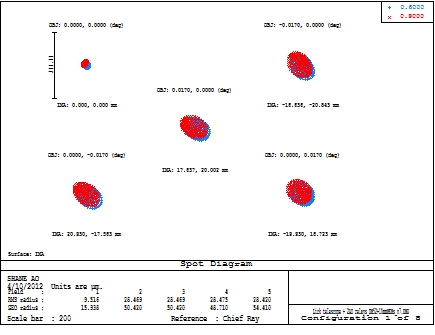

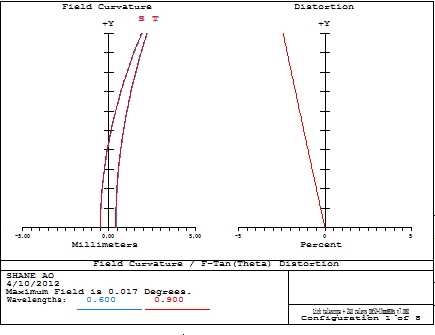

There are several challenges in the design and performance of the focus sensor. As described in 7.1.3 the TTFS consists of only one powered optic, which scans the 120” field of view mounted to the Little Joe detector. However, the image plane provided by the adaptive optical OAP relay suffers from aberrations and field curvature which must be taken into account for the focus measurement to be valid. Figure 23 and Figure 24 demonstrate the difficulty, showing the geometric spot and field curvature analyses, respectively, of the 120” field of regard imaged by the 1st OAP relay. As one moves the TTFS detector and reimaging lens across the patrol field, the focus of the first OAP relay shifts, adding a spurious focal error signal. Having the ability to refocus the TTFS at each field position would alleviate the problem, but is mechanically difficult. To determine if the error signal can be calibrated out, a series of Fresnel propagation simulations were performed.

Figure 23. The geometric spot analysis at the focal plane of the first OAP relay. At the extreme field points of the 120” field of view the image suffers from astigmatism and field curvature.

Figure 24 Analysis of the field curvature (left hand plot) at the focal plane of the first OAP relay. At extreme field points the image focus is shifted by almost 3 mm.

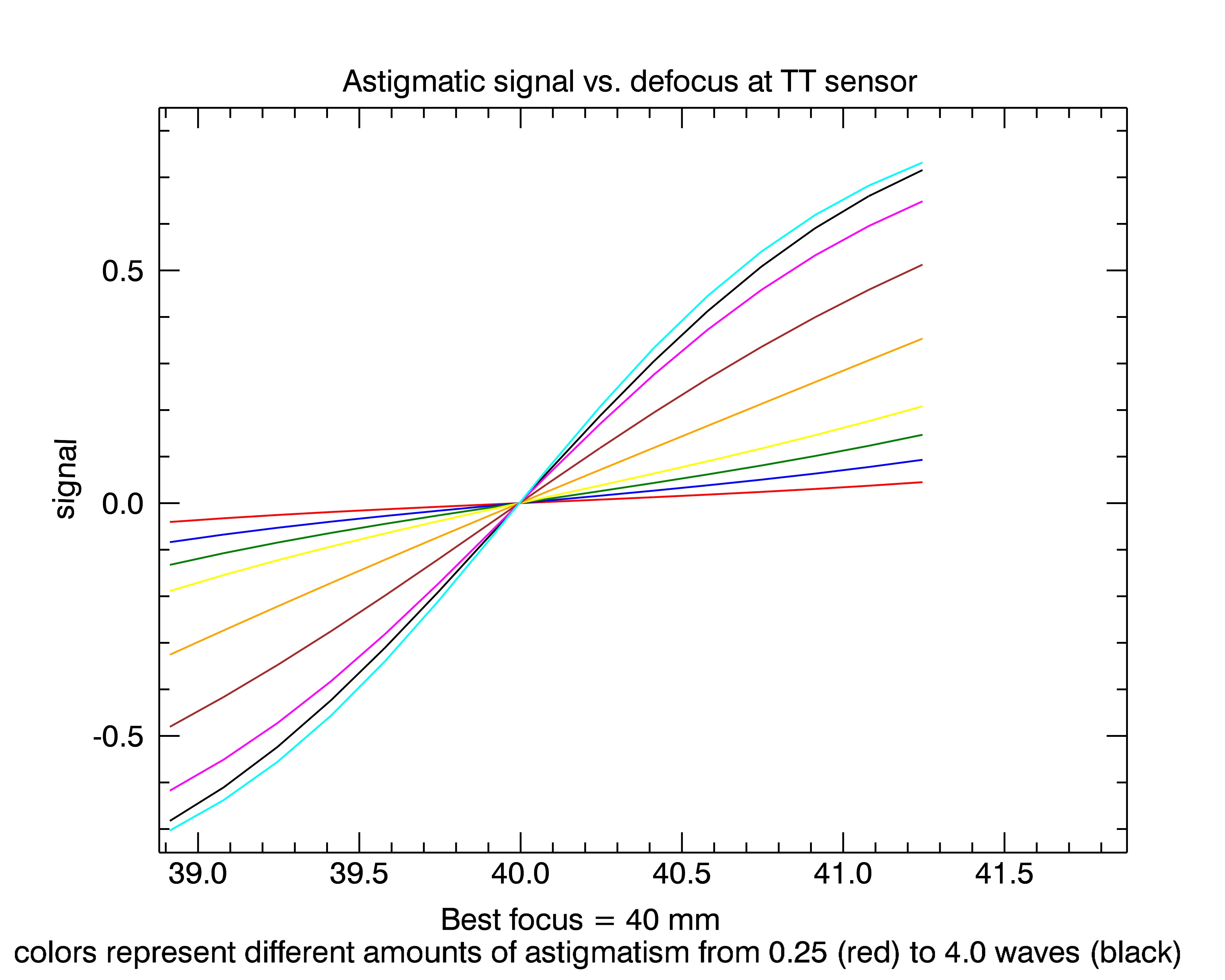

The results of the Fresnel analysis are shown in Figure 25. A number of simulations were done for different amounts of applied astigmatism (from 0.25 to 4.0 waves). As can be seen, the sensitivity of the sensor increases with increased astigmatism, but the signal becomes non-linear at less defocus. To calibrate the effects of field curvature, the sensor must remain in the linear signal region even with the added defocus due to field curvature. The field curvature will introduce approximately 3 mm of defocus at the extreme field points of the 120” field. Because there is a change in f/# between the OAP relay and the focal plane of the TTFS detector, each 1 mm of defocus at the OAP relay focal plane corresponds to 30 μm of focus shift at the Little Joe (the lateral magnification goes as the square of the paraxial magnification). It can be seen in Figure 25 that the linear regime of signal extends for a couple of millimeters, even for large amounts of applied astigmatism. Thus the field curvature can be calibrated for. As can focal shifts due to the insertion of filters before the tip/tilt/focus sensor or IRCAL. Still to be determined, however, is whether the additional astigmatism at the edges of the field can be tolerated.

Figure 25. Fresnel propagation analysis of the astigmatic focus sensor signal versus defocus at the focal plane of the Little Joe detector. Different colors represent different amounts of applied astigmatism.

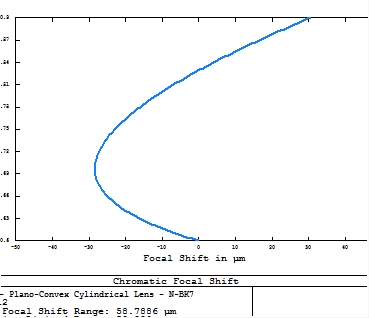

Another challenge in designing the tip/tilt/focus sensor was the broadband nature of the natural star light. The dichroic beamsplitter will transmit 0.6 – 0.9 μm light, and the broadband light must provide accurate focus measurement. The astigmatic lens has therefore been designed as an achromat. Figure 26 shows the residual chromatic focal shift for the TTFS of about 50 μm P-V. This results in Figure 27, the behavior of the defocused geometric spots for defocus values on order of a depth of focus. Depending on the color of the natural guide star, a baseline “in-focus” signal can be determined, and defocus around the baseline will be detected.

Figure 26. Chromatic focal shift of astigmatic lens in TTFS.

Figure 27. TTFS spots for a focal shift on order of the depth of focus (~30 μm).

Wavefront Sensor Optical Path¶

As described in section 7.1.4.6, there will be two wavefront sensor configurations when Shane AO sees first light on the telescope, with the option to upgrade to three configurations at when laser return is sufficient. The main concern within the wavefront sensor is the performance of the optical relay between the lenslet array and the wavefront sensor detector. The lenses of the relay must provide the correct magnification to image the lenslet arrays onto the fixed subapertures of the detector. Distortion, field dependent aberrations, and chromatic aberrations should be minimized to provide a near-perfect grid of Hartmann spots on the detector.

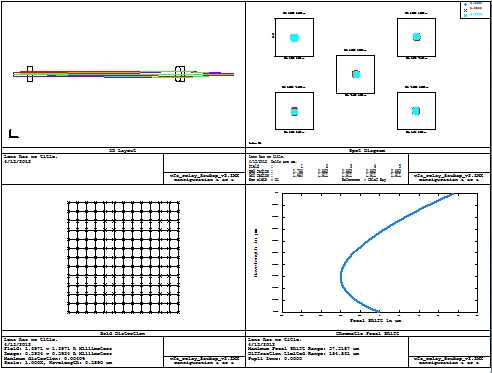

Figure 28 and Figure 30 provide a performance analysis for the relay lenses alone for the 8x8 and 16x16 subaperture configurations, respectively. Each report plot shows the layout in the top left, geometric spot diagrams as compared to the pixel size on the Scimeasure CCID66 (box) in the top right, a distortion map on the bottom left which indicates that the distortion over the entire array of Hartmann spots is well under 0.01%, and the chromatic focal shift over the 0.589 – 0.9 μm is about 60 μm, less than the depth of focus.

Figure 28. Analysis of the 8x8 subaperture configuration spot relay, showing layout (*top left*), geometric spot analysis for the central and outer subapertures with the scale box the size of a single wavefrtont sensor pixel (*top right*), grid distortion (*bottom left*) and chromatic focal shift (*bottom right*) over the 0.589-0.9 micron wavelength range.

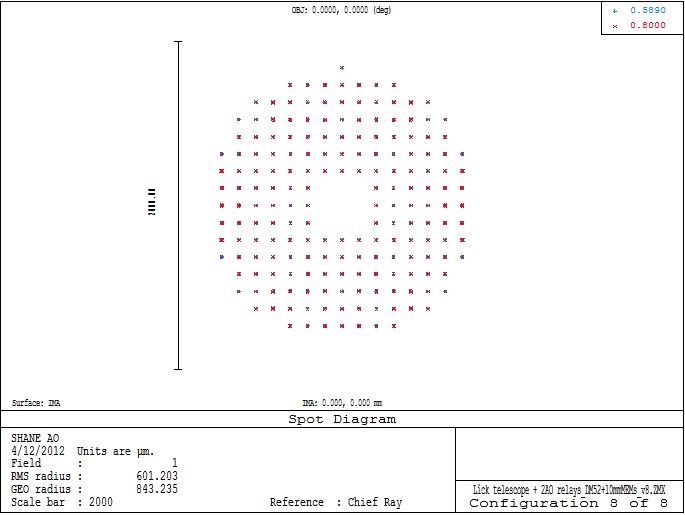

Figure 29. Hartmann spots produced in Zemax when wavefront sensor model is coupled with telescope and adaptive optics system, 8x8 subaperture case.

Figure 30. Analysis of the 16x16 subaperture configuration spot relay, showing layout (*top left*), geometric spot analysis for the central and outer subapertures with the scale box the size of a single wavefrtont sensor pixel (*top right*), grid distortion (*bottom left*) and chromatic focal shift (*bottom right*) over the 0.589-0.9 micron wavelength range.

Figure 31. Hartmann spots produced in Zemax when wavefront sensor model is coupled with telescope and adaptive optics system, 16x16 subaperture case.

Figure 29 and Figure 31 show the resulting Hartmann spots on the Scimeasure wavefront sensor detector when the wavefront sensor optics is coupled with the entire AO relay and telescope in Zemax. Spot pitch is 105 μm for both configurations (four pixel subapertures plus one pixel guard band).

Pupil Image Analysis¶

Adaptive optics systems contain many surfaces which are conjugate to the entrance pupil of the telescope, and for which good pupil imaging is imperative. In ShaneAO these include both deformable mirrors, the lenslet arrays in each configuration, and the cold stop located within the IRCAL dewar.

In order to analyze the imaging of the entrance pupil, the Zemax design of the adaptive optics relay, wavefront sensors and IRCAL were set up so that the primary mirror became the object, and the telescope focus became the aperture stop with a diametr equal to the science field of view. The field points were defined as the center and outer diameter of the primary mirror.

In this mode, spot diagrams now show how a point on the primary mirror will be imaged at the surfaces conjugate to the primary. Grid distortion and field curvature plots indicate the distortion, tilt, and curvature of the pupil plane at each of the surfaces. For an adaptive optics system to provide good correction, the primary mirror should be imaged with an amount of blurring and distortion which is small compared to the scale of a subaperture or actuator. Inside the IRCAL dewar, the blurring of the pupil image will determine the amount of undersizing of the cold stop necessary to adequately block the thermal background.

Woofer DM¶

Figure 32. Pupil imaging on the woofer mirror. The footprint of the overlapping pupil images from on-axis and four extreme field points is shown in the *top left*, with the black circle the size of the ALPAO clear aperture *Top right* is the spot produced by five points on the primary mirror – one on-axis and four at the edge of the pupil – with a box the size of the actuator pitch of the deformable mirror. *Bottom left* indicates the distortion of the pupil image. *Bottom right* shows field curvature and distortion plots. The field curvature plot is dominated by pupil tilt.

The first pupil image in the system falls on the ALPAO woofer DM, with a 2.5 mm actuator pitch. The footprint diagram in the upper left of Figure 32 shows that extreme field points overlap at the pupil. The top right confirms this, showing spots that are very small (compared with the actuator size) for the 28” diameter science field. The grid distortion, shown in the bottom left, is 0.18%, showing little distortion of the pupil. The pupil does, however have a large amount of tilt at the woofer DM (and the tilt of the DM is unfortunately in a direction that worsens this effect). Projected on the sky, the pupil tilt is equivalent to a 136 m tilt in the plane being corrected.

Tweeter DM¶

Figure 33 shows the same analysis for the pupil imaged on the tweeter mirror. The footprint diagram indicates that pupils from extreme field points overlap, and show how the pupil is placed within the 32x32 actuators. The geometric spots are compared to the actuator pitch (box) of 0.340 mm. Pupil distortion on the MEMs is 0.12%, and as can be seen pupil tilt is negligible (the pupil curvature is visible in the field curvature plot and is approximately 200 μm in sag.

Figure 33. Pupil imaging on the tweeter mirror. The footprint of the overlapping pupil images from on-axis and four extreme field points is shown in the *top left*, with the black square the size of the MEMs active area. *Top right* is the spot produced by five points on the primary mirror – one on-axis and four at the edge of the pupil – with a box the size of the actuator pitch of the deformable mirror (0.340 mm). *Bottom left* indicates the distortion of the pupil image. *Bottom right* shows field curvature and distortion plots. The field curvature plot is dominated by pupil tilt.

Wavefront Sensor¶

Also of interest is the behavior of the pupil image on the lenslet array of the Hartmann sensor. If the pupil image is overly blurred or distorted at the lenslet array, we may not be sampling the pupil adequately. Figure 34 shows the spot diagram of the primary mirror imaged onto the lenslet array in the 8x8 configuration, and a distortion map for the pupil image. The scale bar in the spot diagram indicates the size of a single lenslet in the array. Pupil distortion on the lenslet array is only 0.12%. The 16x16 subaperture mode has very similar results. We are not making any gross errors in sampling the pupil at the lenslet array.

Figure 34. Pupil image quality and distortion at lenslet array for 8x8 subaperture configuration.

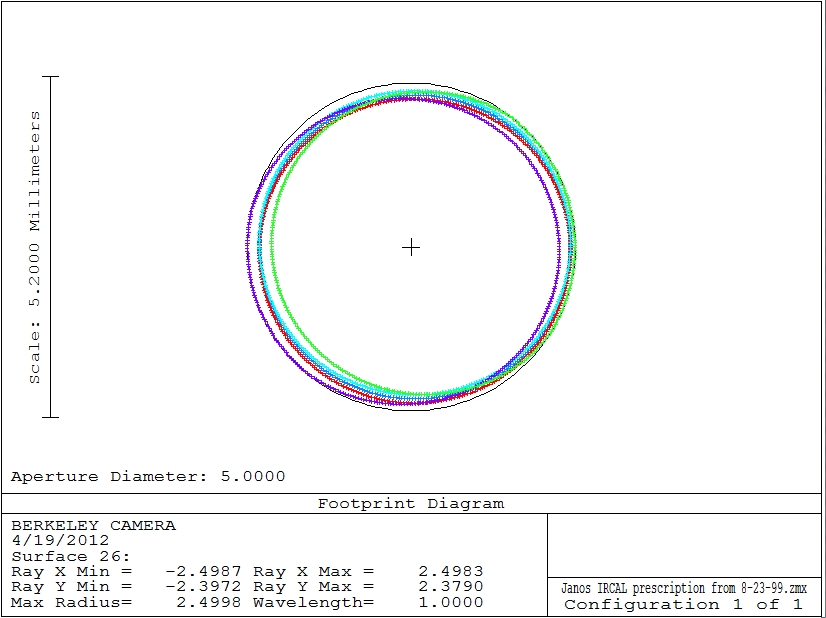

Science Camera Cold Stop¶

Figure 35 shows the behavior of the pupil at the cold stop within IRCAL. The amount which the pupil at the cold stop is aberrated, tilted or distorted determines the amount the cold stop must be undersized to avoid inadvertently letting in stray thermal light. Undersizing, however, reduces the overall throughput of the system. Upper right in Figure 35 shows that the pupils from extreme field points do not overlap exactly. This is due to the field dependent aberrations shown in the upper right (with a 100 μ scale bar) and the pupil tilt (0.3 mm over the 3.85 mm pupil) shown in the bottom right (graph on left). Distortion is small (0.1%). As a result, the cold stop will be undersized by at least 200 μm.

Figure 35. Pupil behavior at cold stop located inside the IRCAL dewar. *Upper left* is a footprint diagram showing overlapping pupils from extreme field points of the 28” diameter field of view. The pupil is approximately 3.85 mm in diameter. *Upper right* shows geometric spots produced by five points on the primary mirror – one on-axis and four and the edges – with the scale bar showing 100 μm. The *lower left* plot shows the pupil distortion, and the *lower right* gives an indication of pupil curvature or tilt, and distortion.

Throughput¶

The system throughput is evaluated in the throughput and emissivity spreadsheet (*link*).

Tolerancing¶

There are two kinds of tolerancing issues we address: The tolerances needed for the fabricated mechanical mounts and the tolerances required on manufactured optical components.

Mechanical tolerances¶

Detailed tolerance requirements for the mechanical design are given in the ShaneAO spreadsheet, under the “Optics List” tab. Most of the mounting tolerances are standard optical tolerances.